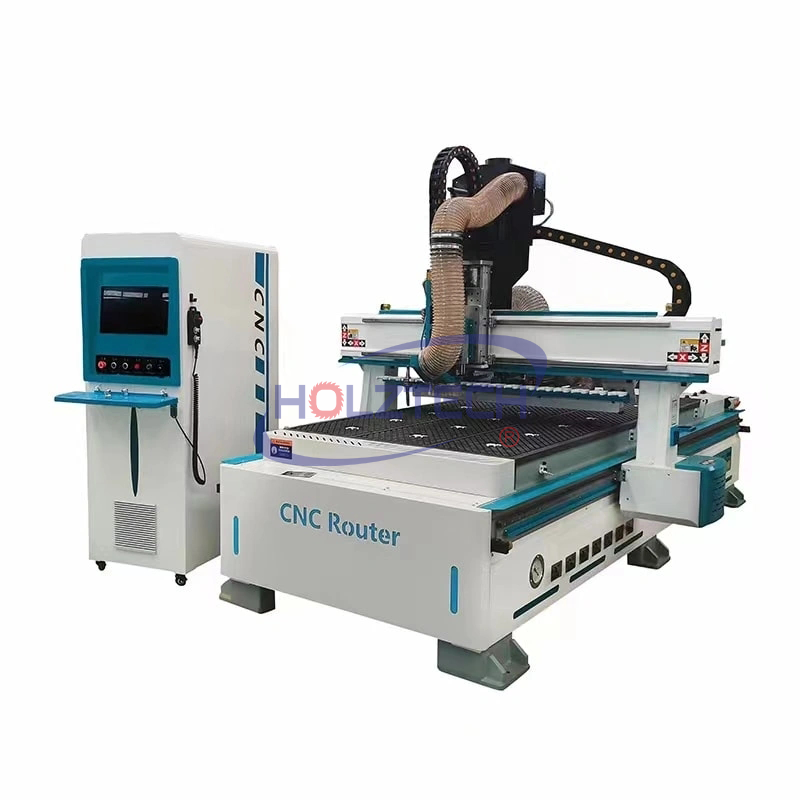

Introducing the HT-1325N: A New Benchmark in Precision and Efficiency for CNC Routing

The manufacturing and fabrication industry has a powerful new tool with the introduction of the HT-1325N CNC Router. Engineered for high performance and reliability, this machine is designed to meet the demanding needs of professionals working with a diverse range of materials, from wood and plastics to non-ferrous metals. With its robust construction and advanced feature set, the HT-1325N is poised to become an indispensable asset for workshops aiming to enhance their production capabilities and output quality.

Precision Engineering for Superior Performance

At the heart of the HT-1325N lies its exceptional precision and power. The router boasts a substantial working area of 1300mm x 2500mm x 350mm (X, Y, Z), providing ample space for large-scale projects. It is driven by a high-power 9KW HQD spindle and achieves a remarkable positioning accuracy of ±0.02mm, ensuring every cut is clean and exact. Coupled with a maximum moving speed of 80m/min, this machine delivers both the speed for efficient production runs and the pinpoint accuracy required for intricate detailing.

Advanced Features for Unmatched Reliability and Convenience

The HT-1325N is equipped with a suite of high-end components that guarantee smooth operation and minimal downtime. It features a Delta 11KW variable frequency drive, a precision Japan Shimpo reducer, and Leadshine 1.5KW servos for superior motion control. A key highlight is the Linear ATC (Automatic Tool Changer) with 8 tools, which significantly reduces manual intervention and boosts productivity. Additional conveniences like an automatic tool sensor, gear and rack drive system, and an automatic lubrication pump ensure the machine operates reliably and consistently over time.

Versatile Application Across Multiple Materials

Versatility is a cornerstone of the HT-1325N's design. Its cutting parameters are expertly calibrated for a wide array of materials, including MDF, acrylic, plastic, aluminum, and MgO boards. The machine efficiently handles various thicknesses, from delicate 1mm sheets up to robust 70mm blocks, adapting its speed for optimal finish and tool longevity. This makes it an ideal single-machine solution for industries ranging from sign-making and furniture manufacturing to aerospace prototyping, offering unparalleled flexibility to tackle any job that comes its way.

By Tina