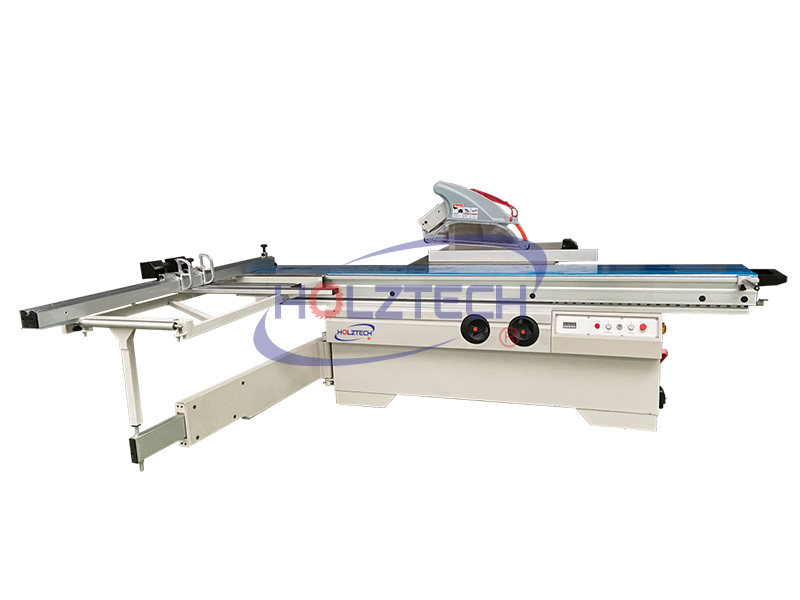

Breakthrough in Intelligent Manufacturing: The All-New Fully Automatic Five-Function Edge Banding Machine Launches, Defining a New Standard for High-Efficiency and Precision Edge Banding

We have officially launched our revolutionary product—the "Precision Engineering" series fully automatic five-function edge banding machine—to the global woodworking and furniture manufacturing industry. This equipment integrates five core functions: preheating, gluing, end cutting, precision finishing, and edge polishing. With an astonishing processing speed of up to 12 meters per minute and superior edge banding quality, it aims to significantly improve production efficiency and reduce overall costs for enterprises, marking a new stage in intelligent edge banding solutions.

Core Technology: Five Steps in One, Precise and Efficient

The design philosophy of the "Precision Engineering" series edge banding machine lies in seamlessly integrating complex processes to achieve one-button automated operation:

Intelligent Preheating: Precisely heats the edge banding tape to ensure it reaches optimal bonding, laying a solid foundation for subsequent gluing, especially suitable for low-temperature environments.

Uniform Gluing: Employs a high-precision quantitative gluing system to ensure a uniform and complete glue layer, guaranteeing the permanent bonding strength of the edge banding tape from the source.

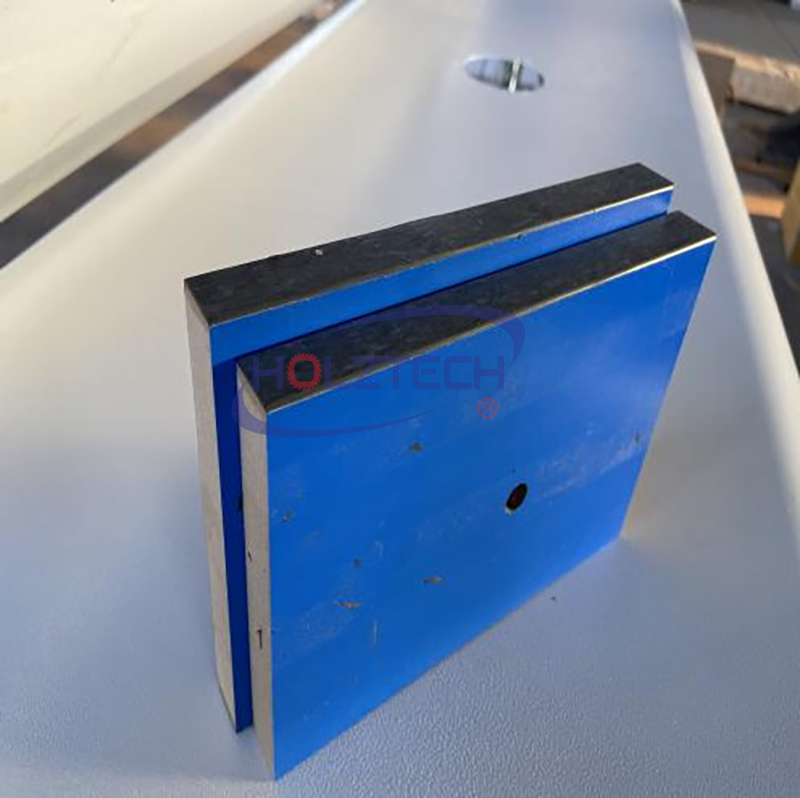

Precision End Cutting: High-speed synchronous cutting achieves millimeter-level flushness between the edge banding and the board surface, making the seam virtually invisible.

Fine Trimming: Refined trimming of the top and bottom edges of the edge banding ensures a perfect fit and smooth transition to the curved surface of the board.

Scraping & Polishing: The final process removes excess adhesive and applies a high-gloss polish to the edge banding surface, resulting in a mirror-like finish.

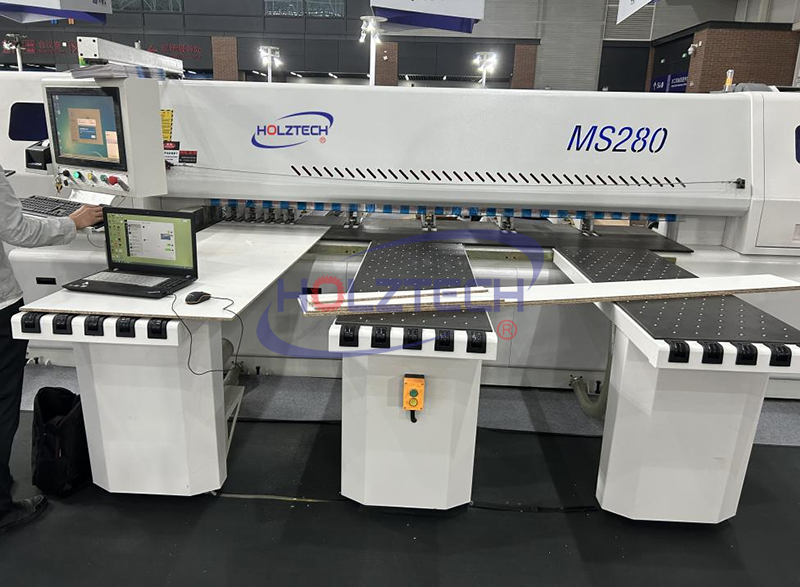

Superior Performance: A Perfect Balance of Speed and Quality

The most remarkable feature of this equipment is its consistently stable processing speed of 12 meters per minute, offering up to 40% greater efficiency than traditional equipment. Even at such high speeds, its high-rigidity mechanical structure and precise motion control system maintain top-quality edge banding with no bubbles, no glue seams, and smooth, flat edges, completely resolving the long-standing industry dilemma of "the trade-off between speed and quality."

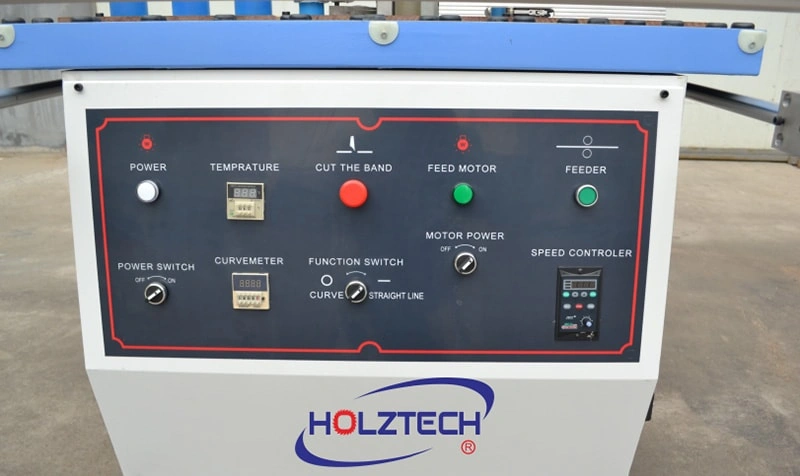

Reliable Core: Top-Tier Electrical Configuration Ensures Stable Operation

To guarantee the ultimate stability and durability of the equipment under long-term, high-load production environments, the core electrical system of this machine utilizes internationally renowned brands:

Drive and Control: Employs Delta's high-performance servo system and PLC, ensuring precise movements and rapid response.

Sensing and Safety: Key position sensors are selected from Omron products, achieving accurate detection and reliable safety interlocks throughout the process.

Electrical Components: Main circuit breakers, contactors, etc., are all provided by Schneider Electric, providing robust electrical safety assurance for the entire machine.

This top-tier configuration not only minimizes the failure rate but also ensures that the equipment can handle 24/7 continuous production tasks.

Innovative Details: Humanized Design Solves Production Challenges

The equipment reflects a deep understanding of the actual needs of users in its details:

Large-Capacity EVA Glue Tank: The standard glue tank capacity is approximately 3 liters, reducing downtime due to frequent glue refills and suitable for mass production.

Optional Teflon-coated glue tank: This innovative option effectively prevents the EVA hot melt adhesive from cooling, accumulating, and carbonizing on the tank walls, greatly simplifying cleaning and maintenance, reducing glue waste, and maintaining optimal adhesive performance over the long term.

By Tina