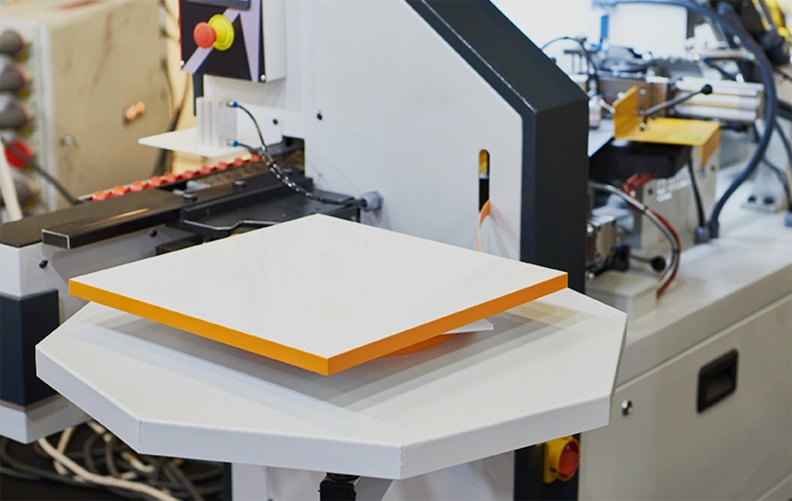

Qingdao Holztech Machinery Co.Ltd is a leading manufacturer and exporter ot woodworkingmachinery and Tools in China. We established long term business relationship with importers ofmachinery, furniture manufacturers all over the world for many years. Our export products are mainlywood based panel machinery like sliding panel saw, edge banding machine, multiple drilling machinehot press machine, dust collection system and etc.

1.Confirm the model and amount.

2.Proforma invoice with our bank account will be sent to you.

3.After receiving down payment, we will start to prepare the machines. When the machines are ready, we take photo and video for you to confirm.

4.After receiving balance, we arrange shipment.

5.Before the machines arrive, you prepare customs declaration, then pick up the machine from the port.

WESTERNUNION,VISA.MASTERCARD.T/T,PAYPAL.APPLE PAY,GOOGLE PAY,GC REAL TIME BANK TRANSFER, MoneyGram, L/C, D/P, D/A

Different machines will require different time. Normally, It will not take more than 30 days before shipment.

The shipping method will vary for different machines. Optional shipping methods are as follows: ordinary Sea shipping by LCL or FCL, DDP service, DHL, UPS, FedEx.

Two years warranty, life long time service.

1.Within the warranty period, if the machine is broken(except consumable parts), we will supply new parts for free, clients should pay for shipping.

2. After the warranty period, we will still provide free technical support and new parts for HOLZTECH machines.