Holztech HT306Y: Compact Power in an Edge Banding Machine

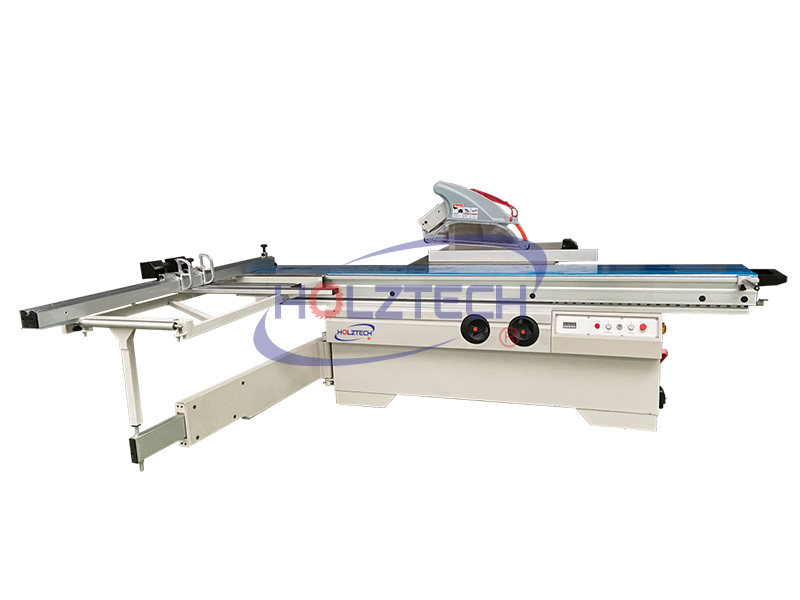

The Holztech HT306Y edge banding machine redefines expectations by delivering heavy-duty processing capability within a remarkably compact footprint. This innovative design allows workshops with limited floor space to access industrial-grade performance previously only available in much larger machines. The edge banding machine achieves this through intelligent engineering that maximizes its internal mechanism efficiency while minimizing its overall dimensions, creating an ideal solution for small to medium-sized furniture manufacturers seeking powerful yet space-efficient equipment.

Automatic Operation with Advanced Pre-Milling Functionality

This fully automatic edge banding machine streamlines production with sophisticated automation, including a valuable pre-milling function. The system prepares panel edges by removing imperfections before applying edge banding material, ensuring flawless adhesion and superior finish quality. By integrating pre-milling into its automated cycle, the edge banding machine eliminates a separate processing step, saving time while guaranteeing consistently professional results across all production runs, from small batches to continuous manufacturing operations.

Digital Interface and Innovative Processing Technology

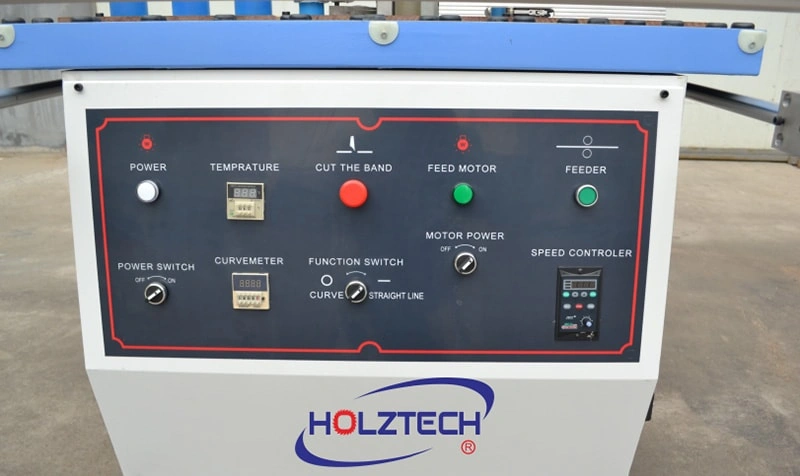

Equipped with a clear digital display screen, this edge banding machine provides operators with precise control over all processing parameters. The interface simplifies setup and monitoring while working in conjunction with specially designed processing components that enhance performance. These innovations allow the edge banding machine to handle various edge materials with exceptional accuracy and finish quality, making complex edge banding tasks more accessible and reliable for operators at different skill levels.

Customizable Functions for Specific Client Requirements

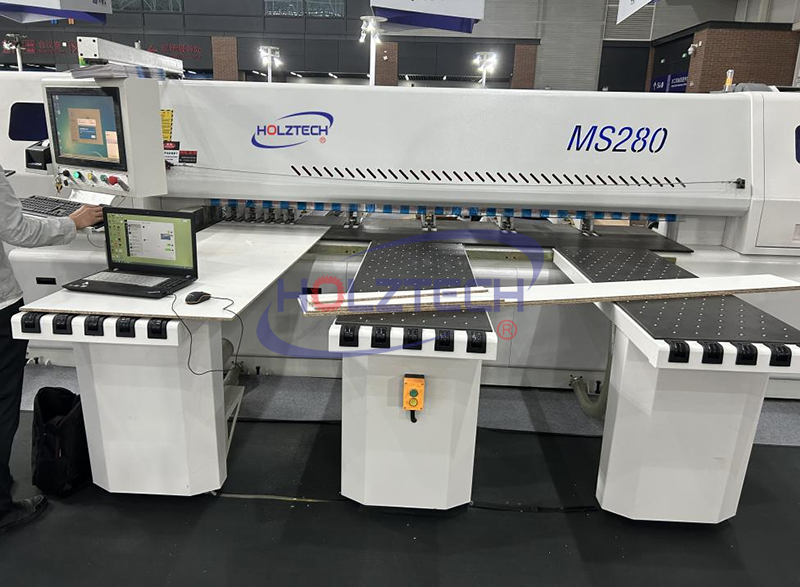

Recognizing that every workshop has unique needs, the HT306Y edge banding machine offers remarkable customization capabilities. Its modular design allows specific functions to be configured according to individual client requirements, essentially tailoring the machine to particular production challenges. This flexibility makes the edge banding machine adaptable to different material types, edge profiles, and workflow demands, ensuring each customer receives equipment optimized for their specific applications in cabinet making and furniture production.

Leo