Holztech's Fully Automatic Finger Grafting Machine for Custom Lengths

The Holztech finger grafting machine offers exceptional flexibility by processing wood segments into desired lengths ranging from 3000mm to 4500mm. This capacity makes it an ideal solution for producing long structural components used in construction, furniture frames, and architectural elements. By automating the critical process of creating extended wooden beams from shorter pieces, this finger grafting machine enables manufacturers to utilize material efficiently while meeting precise dimensional requirements for various industrial and commercial applications.

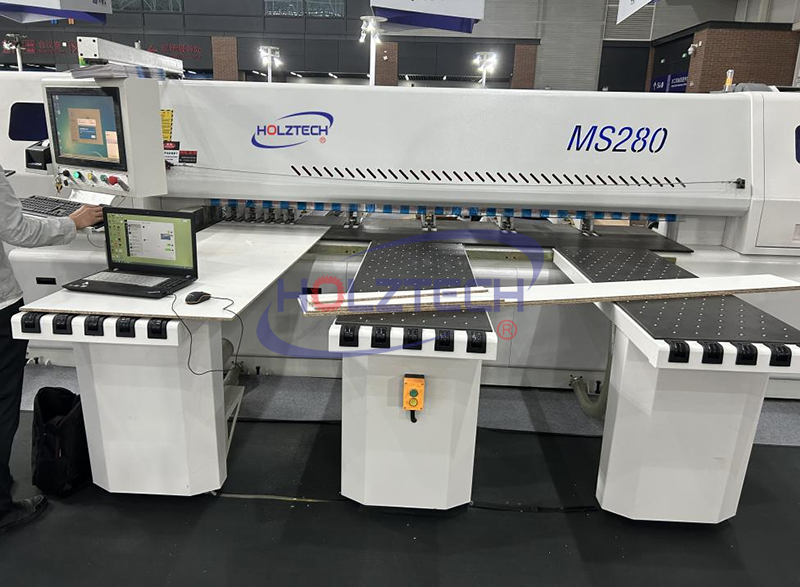

Automated Feeding and Grafting System for Continuous Operation

Engineered for maximum productivity, this advanced finger grafting machine features fully automated feeding and grafting mechanisms. The system seamlessly transfers wood pieces through the entire process—from initial positioning and precise cutting of finger joints to application of adhesive and final pressing. This complete automation transforms the finger grafting machine into a continuous production unit that significantly reduces labor requirements while maintaining consistent joint quality and strength throughout extended operation cycles.

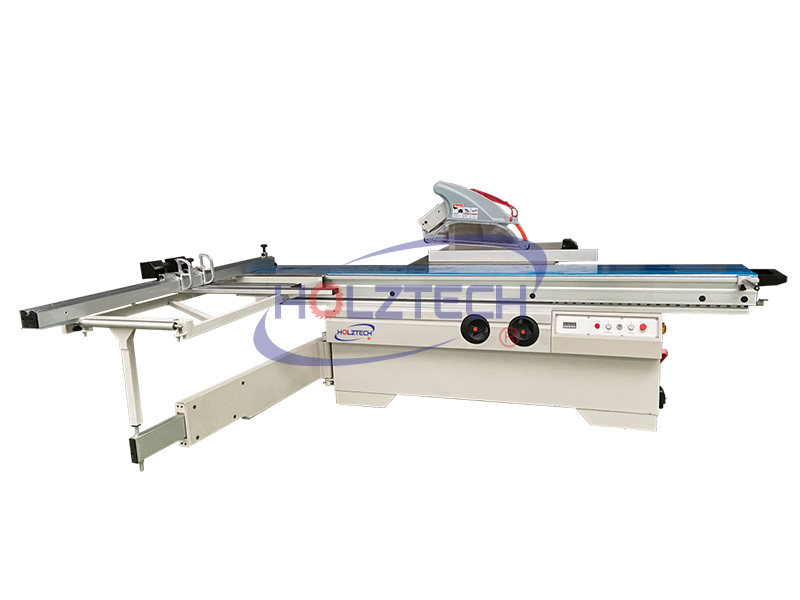

Unibody Construction for Enhanced Durability and Stability

The finger grafting machine incorporates a robust unibody construction that provides superior structural integrity and long-term durability. This solid-frame design minimizes vibration during high-speed operation, ensuring precise alignment of finger joints and consistent pressure application during the bonding phase. The enhanced stability of this finger grafting machine directly contributes to stronger, more reliable wood joints while withstanding the demands of industrial production environments year after year.

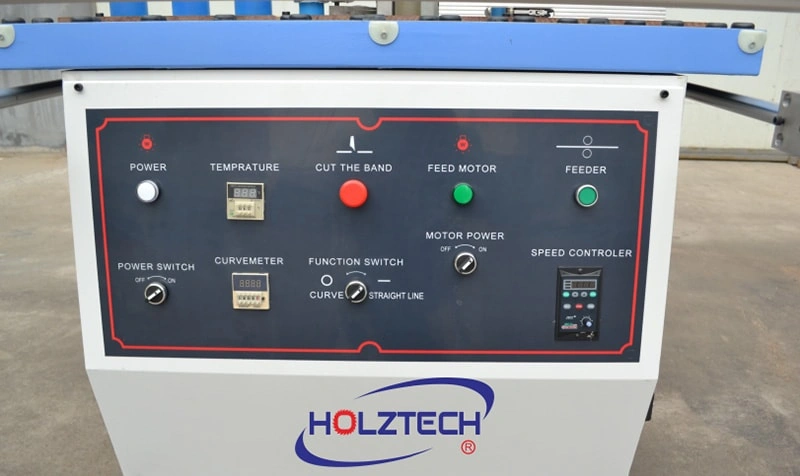

Dual Operational Modes for Versatile Production Needs

Designed to accommodate diverse customer requirements, this finger grafting machine offers both fully automatic and manual operational modes. The automatic mode delivers maximum efficiency for high-volume production, while the manual option provides greater control for specialized projects or lower-volume applications. This flexibility allows workshops of different scales and economic considerations to benefit from professional-grade finger jointing technology, making the machine accessible to both large manufacturers and smaller custom woodworking businesses.