HOLZTECH Unveils HT450CF: A New Benchmark in Automatic Edge Banding Efficiency

HOLZTECH Machinery continues to push innovation in woodworking equipment with the release of the HT450CF automatic edge banding machine. Designed for medium to large-scale production environments, this high-performance machine supports banding tape widths from 12mm to 65mm and handles workpieces as short as 100mm. With a robust feeding speed of 10–23 m/min and compatibility with materials up to 60mm thick, the HT450CF meets diverse industrial needs while maintaining precision and reliability.

Smarter Control, Smoother Operation

Equipped with a Delta PLC control system and a user-friendly touchscreen interface from Taiwan, the HT450CF offers both ease of use and intelligent operation. The machine also incorporates Homag-original drivers for accurate motion control, minimizing the risk of panel damage. From glue application to end trimming and polishing, every function is seamlessly integrated and fully programmable.

High-Quality Components for Uninterrupted Performance

The HT450CF relies on trusted international brands to deliver consistent output. Key elements include CHBNS feeding motors, Festo and Airtac pneumatic components, HIWIN linear guides, and Schneider electrical systems. Additionally, the Teflon-coated glue pot and scraped pressing rollers help minimize glue residue, while an automatic lubrication system maintains moving parts with minimal manual intervention.

Delivering Perfect Edges, Automatically

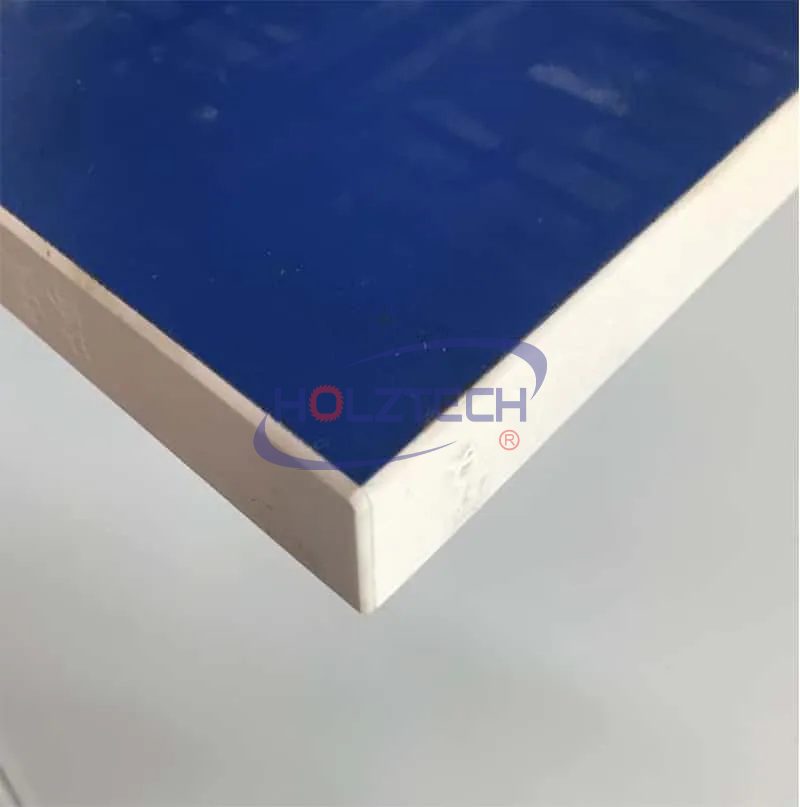

A standout feature is the inclined wheel disc-type fence with large profiling wheels, which allows the corner-rounding function to follow the workpiece’s contour naturally. This design, paired with imported bearings and CNC-machined parts assembled within 0.05mm tolerance, ensures flawlessly smooth and flat edge banding. For manufacturers seeking a reliable, high-speed, and precision-focused edge banding solution, the HOLZTECH HT450CF sets a new standard in automation and finish quality.

By Tina