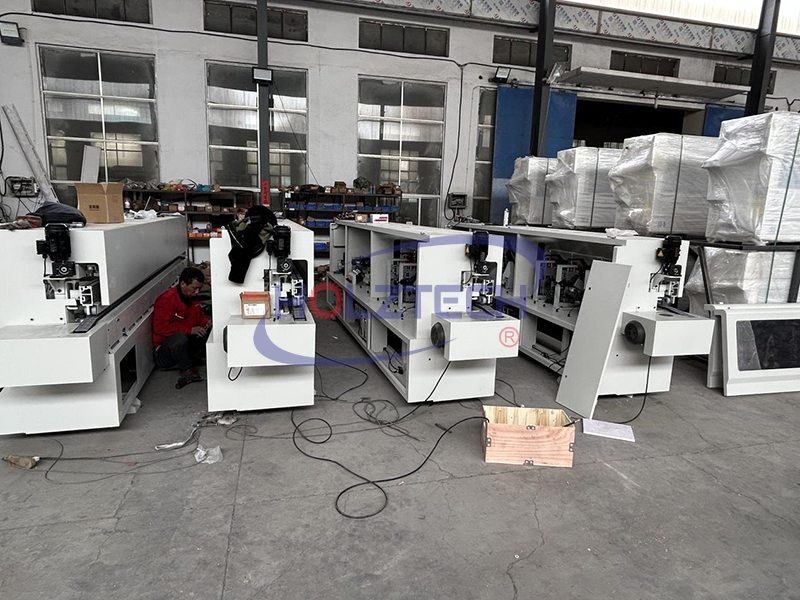

Holztech HT600A: Entry-Level Heavy-Duty Edge Banding Machine

The Holztech HT600A represents a robust entry into heavy-duty edge banding, constructed with a body precision-cut by CNC machinery for exceptional dimensional accuracy. This edge banding machine is engineered to provide the durability and stability required for continuous production environments. Its solid foundation ensures reliable performance, making it an ideal starting point for small to medium-sized workshops seeking to upgrade their capabilities. The machine's design philosophy bridges the gap between basic models and industrial-grade equipment, offering superior value.

14mm Thick Body for Enhanced Stability and Durability

Built with a substantial 14mm thick frame, this edge banding machine delivers unparalleled structural integrity that minimizes vibration during operation. Each processing unit is designed to handle demanding entry-level heavy-duty tasks with consistent results. The remarkable thickness of the components ensures long-term reliability and maintains precision under continuous use, making this edge banding machine suitable for processing various materials from melamine to solid wood edges in furniture manufacturing applications.

Complete Automated Processing with Five Essential Functions

This fully automatic edge banding machine integrates five crucial functions: glue application, end trimming, fine trimming, scraping, and polishing into one seamless operation. The integrated lubrication pump continuously maintains machine smoothness and precision, ensuring consistent quality across production runs. This comprehensive functionality allows the edge banding machine to complete professional-grade edge processing automatically, significantly reducing labor requirements while improving output quality in panel processing and cabinet manufacturing.

Versatile Upgrade Options for Enhanced Performance

The HT600A edge banding machine offers valuable optional upgrades including an electric lifting beam for height adjustment, additional heating lamps for improved glue activation, and a non-stick Teflon glue pot for cleaner operation. These enhancements allow businesses to customize the edge banding machine to their specific production needs, providing flexibaility for future expansion and specialization in custom furniture production and architectural millwork applications.