Daily Maintenance and Daily Maintenance and Troubleshooting Guide for Automatic Edge Banding Machine (HT600A)

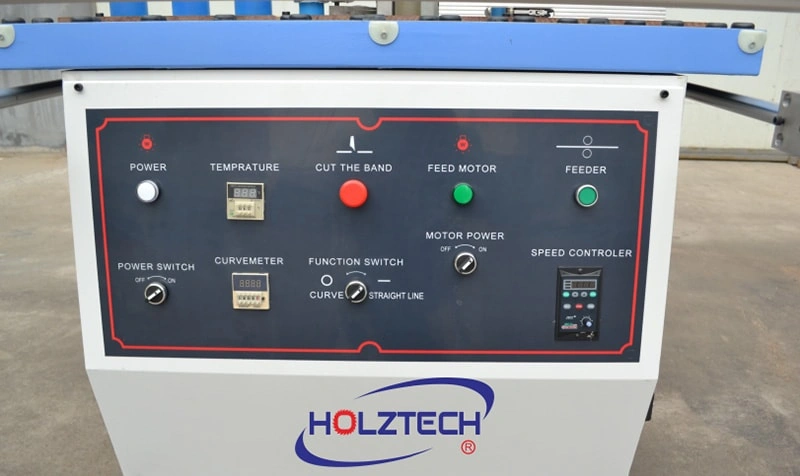

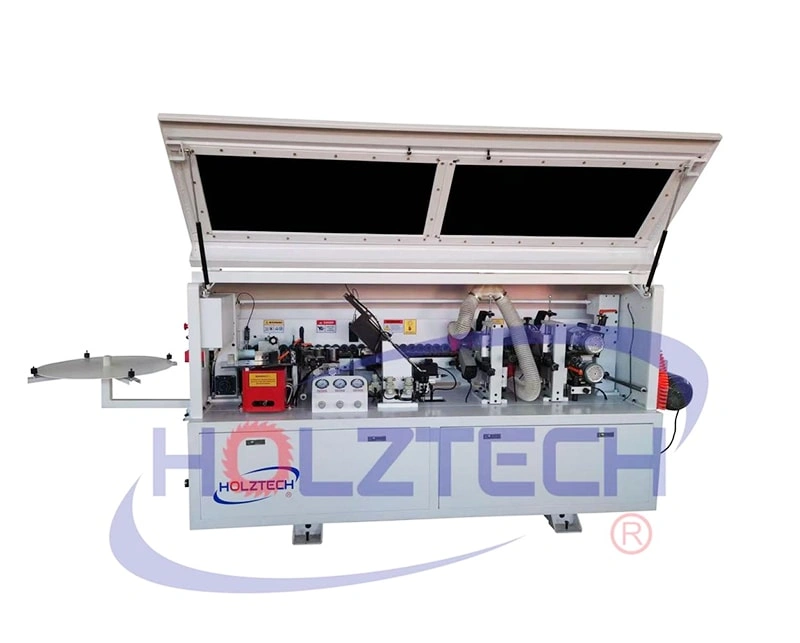

In the production of panel furniture, the automatic edge banding machine has become an essential tool for improving efficiency and ensuring high-quality finishing. Among various models, our HT600A automatic edge banding machine stands out for its reliability and multifunctionality. This model integrates 6 functions: pre-heating, gluing, front and end cutting, fine trimming, scraping, and polishing, making it suitable for both small and large furniture manufacturers. Although many enterprises have adopted such equipment, most are still at an early stage regarding performance adjustment, routine maintenance, and troubleshooting. With proper care, companies can significantly reduce failure rates and increase productivity. As a professional edge banding machine manufacturer and supplier, we summarize the most important aspects of daily maintenance.

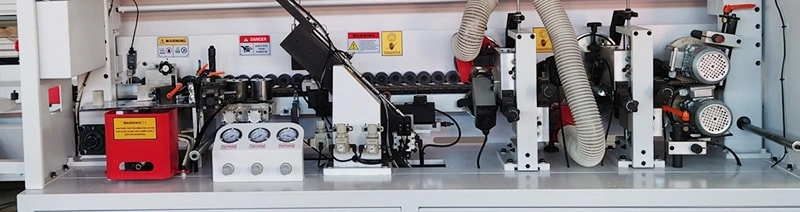

First, proper lubrication of the chain system and glue pot is critical to keeping the machine running smoothly. The conveyor chain should be regularly lubricated with lithium-based grease to ensure smooth movement along the guide rails. The glue pot requires high-temperature grease, and after every 400 hours of operation, the worm gear reducer oil should be replaced with specialized lubricant (ISO VG 460) to extend service life. Additionally, checking whether the central lubrication system has sufficient oil is essential to prevent bearing damage caused by inadequate lubrication. These steps are fundamental to maintaining stable production and the high performance of the edge bander machine.

Second, daily inspections and cleaning should never be overlooked. Operators should monitor water levels in the pneumatic filter unit to prevent moisture from entering the compressed air system. Cutting tools should be checked for wear and replaced when necessary. Before finishing work each day, operators should thoroughly clean the machine, removing dust, offcuts, and excess edge banding strips. Following these practices helps ensure long-term stability and consistent performance of the woodworking machinery in any furniture factory.

By implementing regular maintenance and inspections, companies can keep their edge banding equipment in top condition, reduce unexpected downtime, and improve overall production efficiency. As an experienced edge banding machine manufacturer , we also recommend providing regular operator training. This allows staff to quickly identify and solve common machine issues, helping furniture manufacturers maintain a competitive edge in the market.