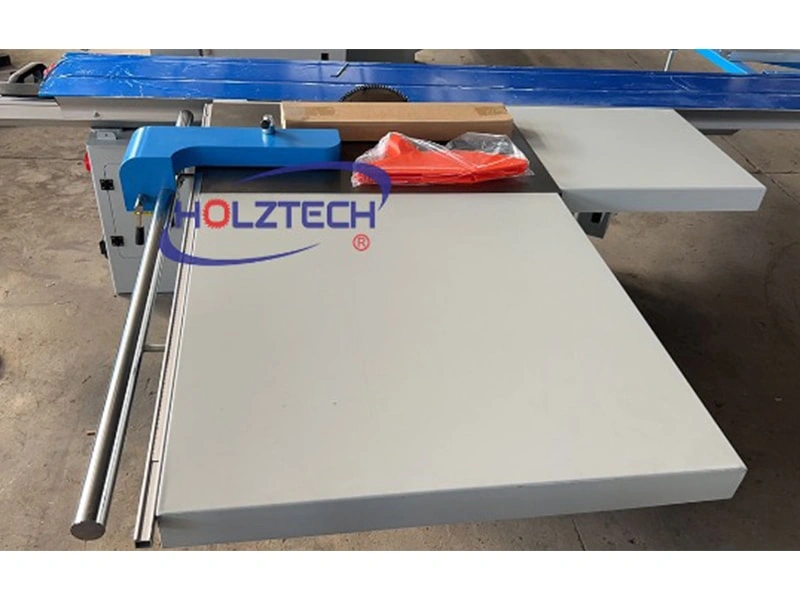

The MJ6132TY sliding table saw for longitudinal, transverse and angular cutting of panel materials (MDF, fibreboard, chipboard and glued panels) faced and laminated, as well as blanks made of solid wood, with preliminary trimming of the lower edge to prevent chipping.

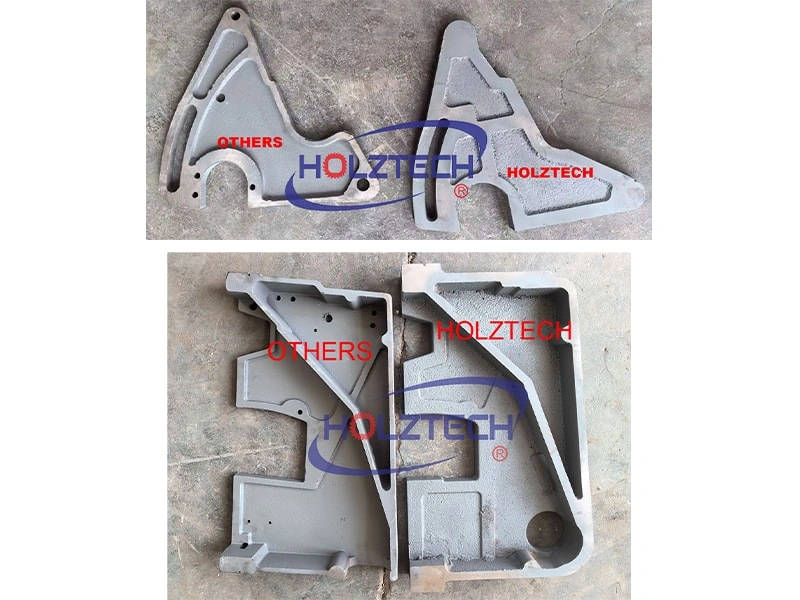

In order to guarantee high quality and precision,full sets cast components are made by ourselves with HOLZTECH logo. Cast iron is stronger and more durable than welding steel.

Stronger cast components than others.

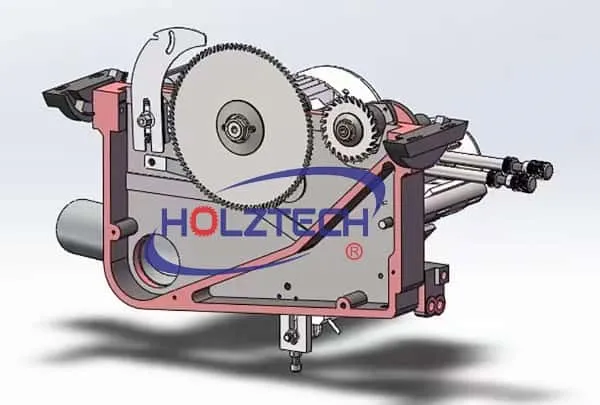

Saw group structure.

The whole saw group is installed on saw body. Much more stable than the other structures which hang under the fixed table.

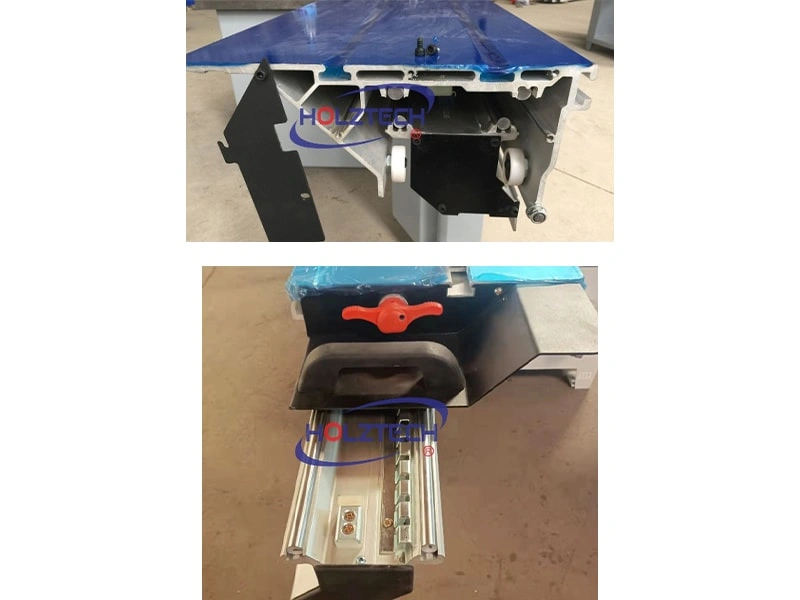

Standard table size is 3200*375mm strong aluminium with two layers,which can stop at any position during cutting.

1800mm cross cut fence for long size board cutting,thick aluminium supporting roll will never deform.

Micro adjustment of rip fence with 1250mm cutting width.

Full size auxilary table with 1250mm rip cutting volume.

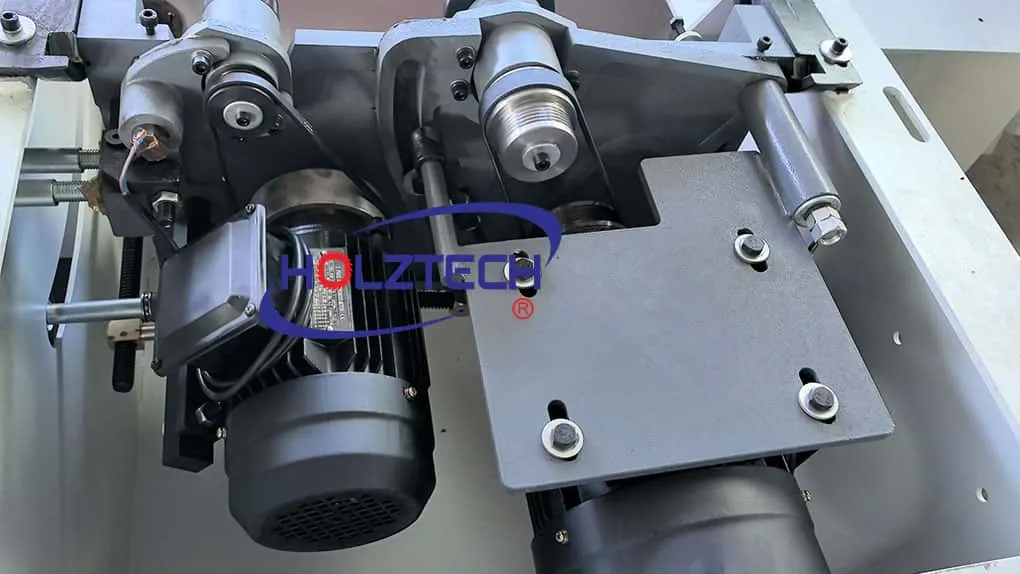

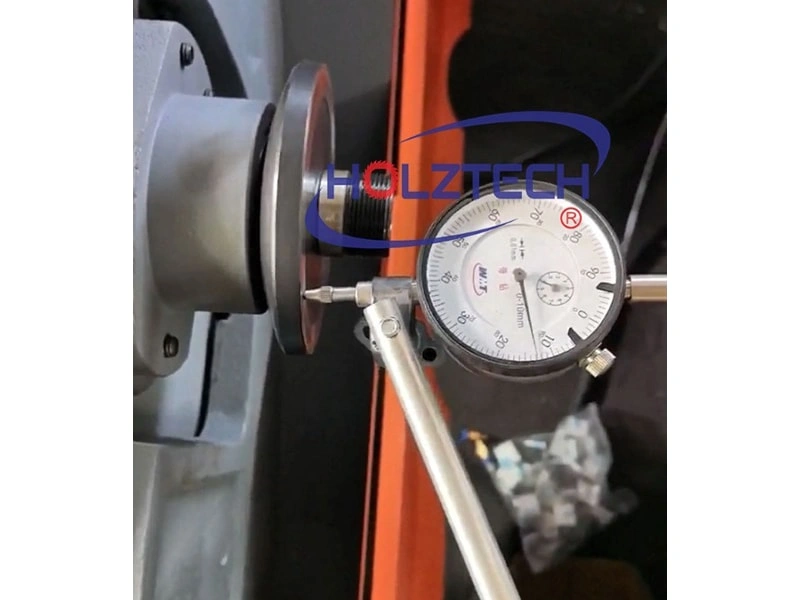

Microcomputer Measuring System to correct the pulley accuracy less than 0.3 g.mm/kg. No vibrating during working. Multiple groove pulley work together with multiple grooves belt to drive the saw discs smoother and with low noise.

All aluminium components oxide layer thickness should be at least 14μm.

6mm thick strong machine body steel,smoothly cut by CNC laser cutting machine with less welding.

Four seats of sliding table are milled by one process on CNC machining center. It guarantees the seats completely at same level.

Remove rust and impurity substance by sand blasting. Electrostatic powder spraying to improve coating corrosion resistant capacity higher and smoother.

Cast components powder coating.

First inspection: pulley flatness inspection.

Second inspection with saw disc.

| Model | MJ6132TY |

|---|---|

| Table Guide Length*Width | 3200mm*375mm(Optional) |

| Max. Cutting Height at 90° | 80mm |

| Main Spindle Diameter | 30mm |

| Main Saw Diameter | 300mm(250-300mm) |

| Main Saw Speed(r.p.m) | 4000/6000 |

| Motor Power(Main+Scoring) | 5.5kw + 1.1kw |

| Scoring Spindle Diameter | 20mm |

| Scoring Saw Diameter | 120mm |

| Scoring Saw Speed(r.p.m) | 8000 |