Designed for high-quality batch cutting of laminated chipboard and fibreboard.

19” big computer screen,it is very clear during using the optimization software. With barcode printer to work with 6 sides drilling machine.

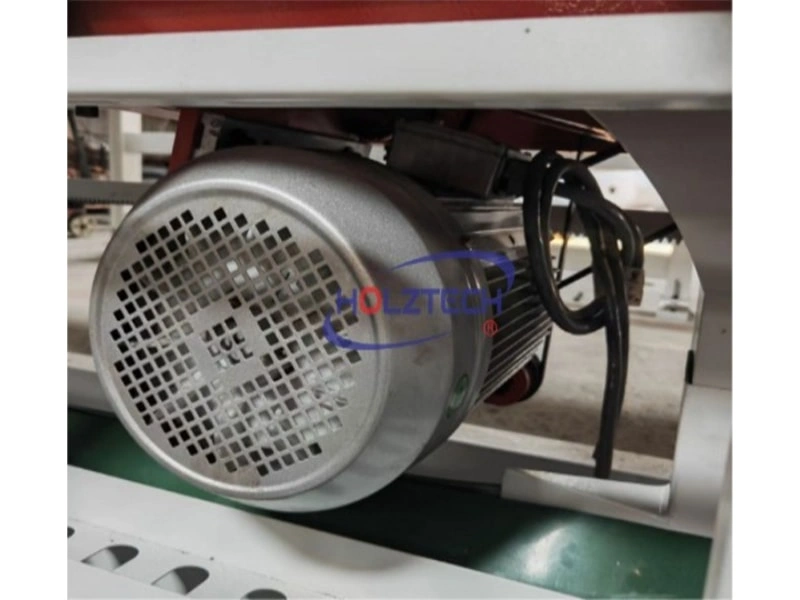

16kw copper wire motor,strong enough to cut 90mm thickness each cutting.

Double saws to cut boards smoothly without chips.

Board clamps to hold and feed the board with high precision.

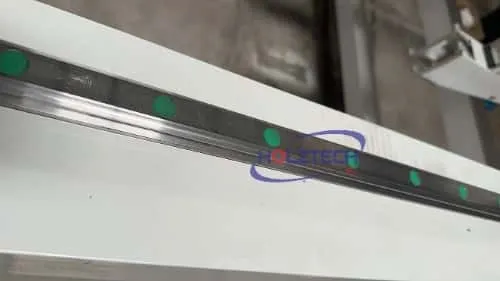

30mm width HIWIN guide rail,wear-resistant and durable with high precision.

The rack is grinded with high precision,with bevel teeth to keep high presion even for cutting big size board.

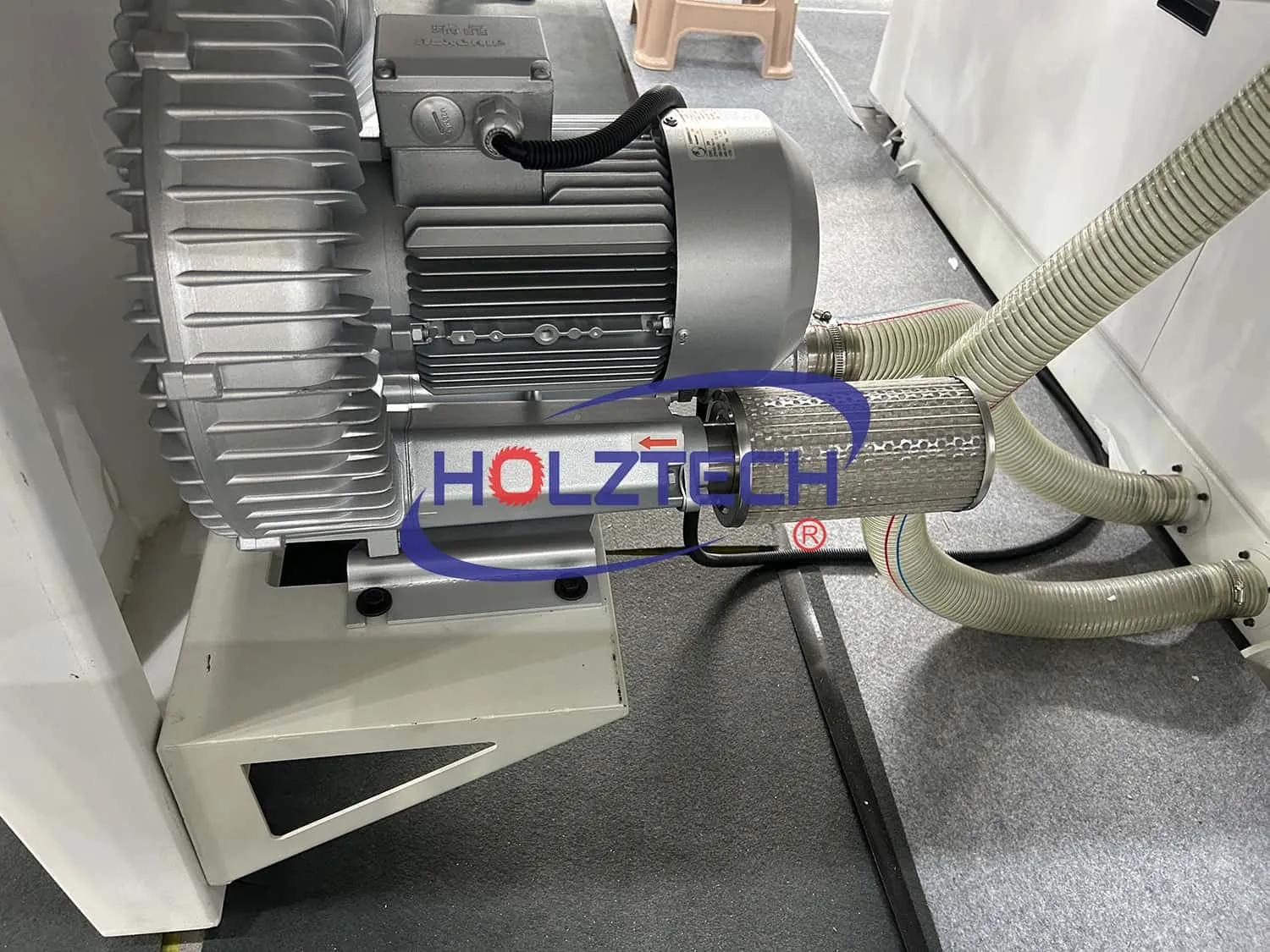

3kw air blower work with the air floating table.

Air floating table to move boards easily without scratches.

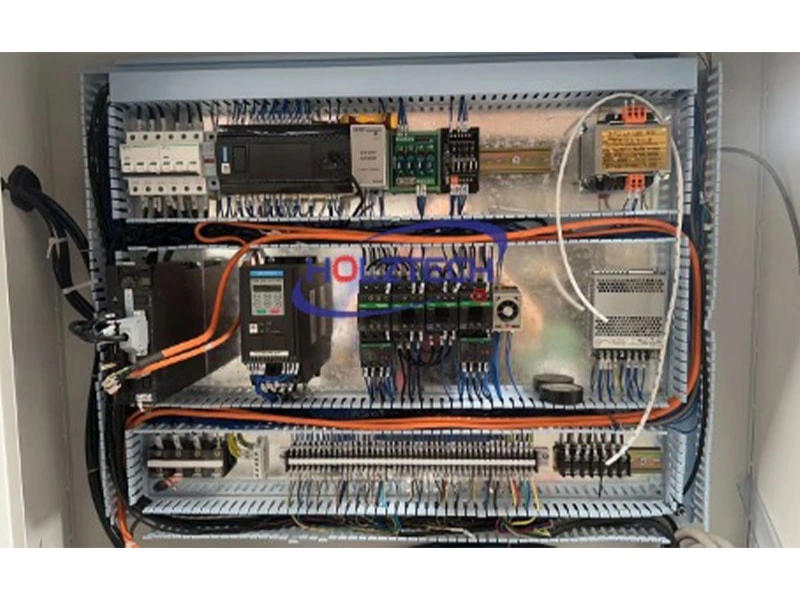

Schneider electrical components.

2kw Inovance servo motor to control the movement with high precision.

| Cutting Length(mm) | 2800 | 3300 | 3800 |

|---|---|---|---|

| Cutting Thickness(mm) | 90 | ||

| Main Blade Diameter(mm) | φ400 | ||

| Main Shaft Diameter(mm) | φ30 | ||

| Main Blade speed(rpm) | 4800 | ||

| Scoring Blade Diameter(mm) | φ180 | ||

| Scoring Shaft Diameter(mm) | φ30 | ||

| Scoring Blade speed (rpm) | 6500 | ||

| Saw Group Forwarding speed(m/min) | 0~100 | ||

| Saw Group Backwarding Speed (m/min) | 60 | ||

| Feeding Speed(m/min) | 60 | ||

| Main Saw Motor Power(kw) | 16 | ||

| Driving Motor Power(kw) | 3 | ||

| Feeding Motor Power(kw) | 1.5 | ||

| High Pressure Air Blower(kw) | 2.2 | ||

| Air pressure(Mpa) | 0.5-0.6 | ||

| N.W.(kg) | 3900/4260/4860 | ||

| Overall size(mm) | 5990x5200x1800/6590x5900x1800/6590*6400*1800 | ||