Six-sides CNC Drilling Machine

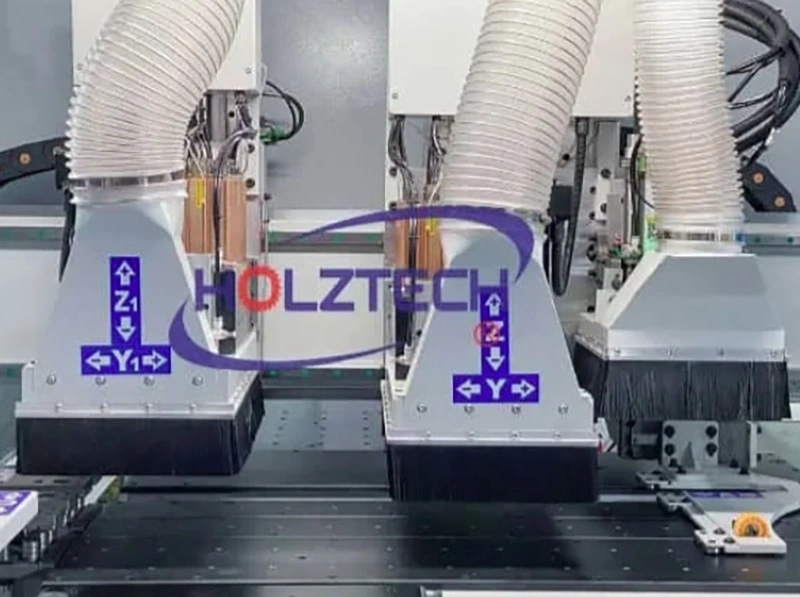

In the rapidly evolving world of panel-based whole-house custom furniture, high-end CNC machining equipment has become crucial for businesses to enhance their competitiveness. The CNC six-sided drilling machine, a high-end CNC multi-spindle drilling system specifically engineered for whole-house customization, has revolutionized traditional processing methods with its core advantages: completing six-sided machining, slot cutting, and profiling in a single operation. One of its standout features is its user-friendly operation and flexible application—requiring no manual intervention throughout the process. It effortlessly handles both mass production and personalized custom orders.

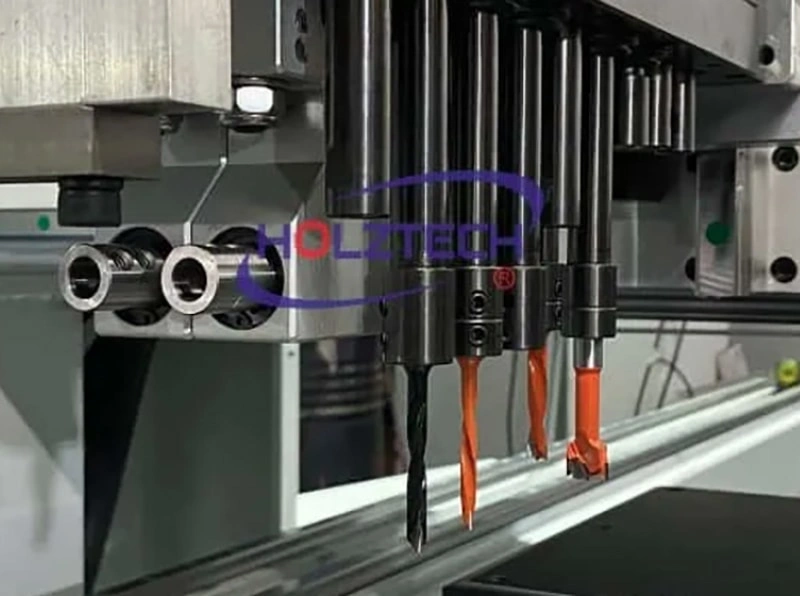

For the frequently occurring hinge hole machining requirements in whole-house customization, CNC six-sided drilling machines demonstrate exceptional adaptability. They support synchronized hinge hole machining, enabling precise positioning and drilling of multiple hinge holes simultaneously to ensure installation accuracy. Additionally, within a specified range of panel thicknesses, the equipment can perform dual-sided mirror machining, ensuring perfectly symmetrical hole positions and groove profiles on both sides of the panel. This capability meets the machining demands for various symmetrical furniture designs.

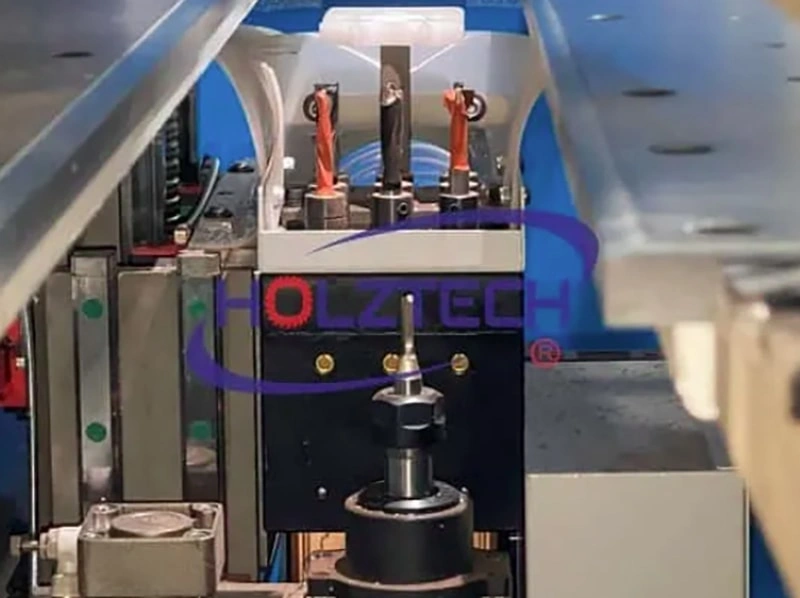

Drilling efficiency remains a core challenge in panel furniture manufacturing, and CNC six-sided drilling machines fundamentally resolve this issue through specialized custom drill-row designs. The machine's drill unit undergoes targeted optimization to minimize avoidance movements based on processing requirements, reducing unnecessary travel and enabling tighter, more efficient drilling cycles. Compared to traditional multi-spindle drilling equipment, processing speeds see a significant boost. Simultaneously, the CNC six-sided drilling machine automatically calculates the optimal drilling sequence. This ensures processing quality while maximizing production cycle reduction, delivering higher output capacity for enterprises.

The equipment features a high-end air-float worktable that employs air-float technology to provide stable support for panels during processing. This effectively prevents panel deformation or displacement, ensuring every hole position and groove profile is precisely accurate. Even more commendable is its automatic output direction optimization function, which flexibly enables front or rear material discharge based on processing requirements, adapting to diverse workshop layouts and production workflows.