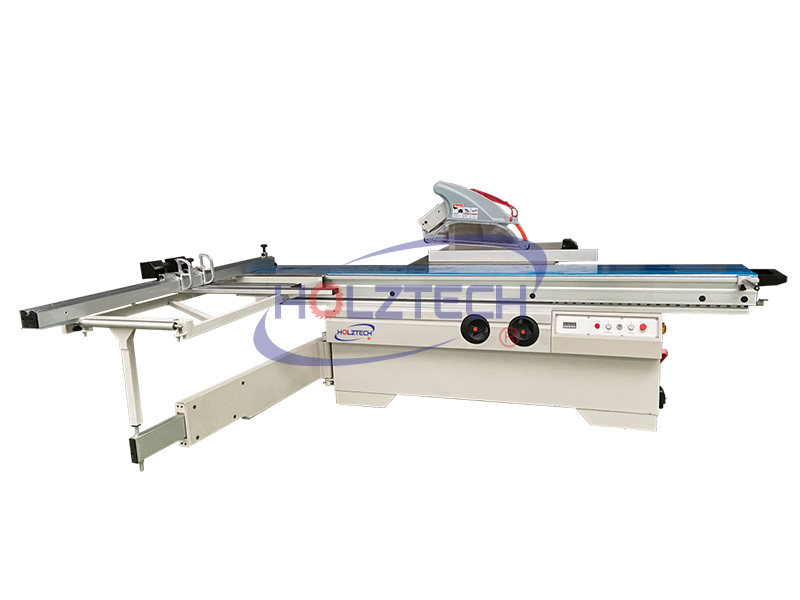

Redefining Efficiency and Precision: The HT450A Industrial-Grade Edge Banding Machine Makes its Grand Debut, Setting a New Benchmark in Furniture Manufacturing

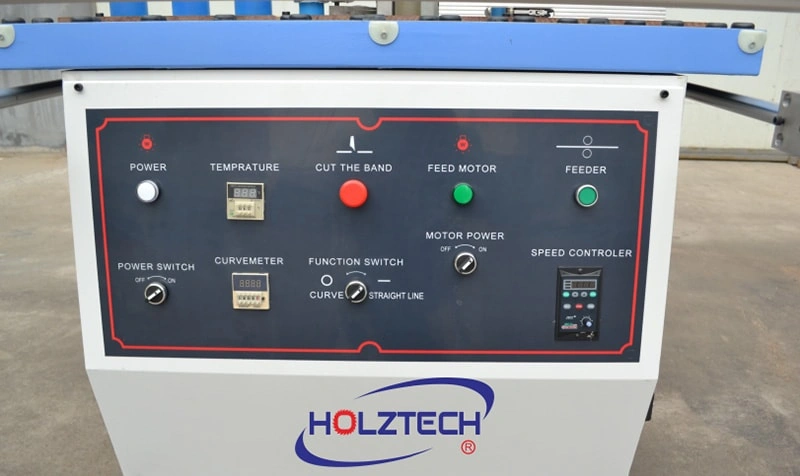

Integrating gluing, end cutting, finishing, edge scraping, and polishing, this machine features top-tier electronic control and intelligent lubrication, achieving superior one-step edge banding quality.

HOLZTECH – a leading provider of industrial manufacturing solutions – today proudly launches its flagship product – the HT450A high-performance fully automatic edge banding machine. Designed to meet the stringent demands of the modern furniture manufacturing industry for high efficiency, high precision, and long-term stable operation, this machine integrates numerous innovative technologies and top-of-the-line hardware configurations, aiming to significantly improve the output quality and reliability of the production line.

The core advantage of the HT450A lies in its superior engineering design and meticulous control over every quality detail. The machine's feed speed can be flexibly adjusted between three levels: 18, 20, and 22 meters per minute, adapting to diverse production rhythms from standard to fast, ensuring maximum production efficiency.

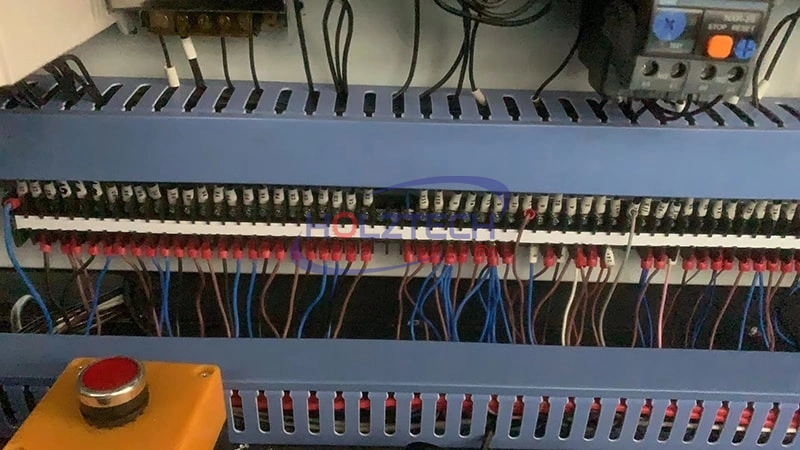

The cornerstone of its stability stems from its robust core. The HT450A's key electrical control systems utilize components from globally renowned brands, including high-quality products from Delta, Omron, and Schneider Electric. This top-tier electronic control system ensures extremely stable power and signal transmission, significantly reducing the risk of downtime due to electrical faults and safeguarding continuous, uninterrupted mass production.

To achieve uncompromising control over the ultimate quality of the product, the vast majority of the core mechanical components of the HT450A are designed and precision-manufactured in-house. This highly vertically integrated production model allows us to strictly control tolerances, materials, and processes from the source, ensuring unparalleled operational precision and an exceptionally long service life.

For the critical end-cutting process, the HT450A features a high-precision beveling system. Its linear guides are precisely arranged at a 45° angle, driving two saw blades controlled by two independent motors to work synchronously. This design can cut away excess edge banding with extreme precision, achieving a near-seamless finish at the joint.

Furthermore, the HT450A incorporates an intelligent automatic lubrication system, allowing users to freely adjust the oil supply frequency according to the actual operating load. This system ensures all moving parts are constantly in optimal working condition, reducing wear, extending maintenance intervals, and further guaranteeing the long-term stability and production continuity of the equipment.

“The HT450A is more than just a machine; it’s the embodiment of our commitment to ‘reliable productivity,’” said the company’s product director. “From top-of-the-line electrical configurations to in-house manufactured precision components, and the user-friendly intelligent maintenance system, every feature is designed to help our customers win market trust and create greater value.”

The HT450A industrial-grade edge banding machine is now available for order, with customized configurations and technical support services offered.

By Tina