MZ73212 Multiple Boring Machine – High-Precision Drilling for Furniture Production

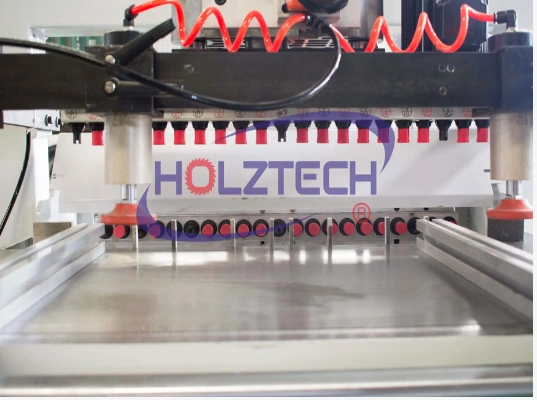

The Multiple Boring Machine is designed for efficient and precise drilling of furniture components. Equipped with two rows of drilling heads, it allows operators to drill both horizontal and vertical surfaces with accuracy. This machine can handle different panel sizes, making it suitable for small to large furniture parts. Its robust construction ensures stability during operation, reducing errors and improving production efficiency.

In addition to standard drilling, the MZ73212 Multiple Boring Machine supports 45° and 90° drilling angles, which is ideal for assembling frame structures, doors, facades, and other furniture products. The machine’s adjustable settings allow for customization according to the material thickness and drilling requirements, providing versatility for various production lines. By combining multi-angle drilling with high-speed operation, manufacturers can save time and reduce labor costs.

The Multiple Boring Machine is also user-friendly and easy to maintain. Operators can quickly set up and adjust drilling patterns, and the machine’s durable components ensure long-term reliability. For furniture factories looking to increase productivity and maintain consistent quality, this multiple boring machine offers a practical, cost-effective solution. It is an essential tool for modern workshops aiming for precision and efficiency in every project.

By Mia

Related News

Following the Spring Festival holiday, HOLZTECH Woodworking Machinery has officially announced a full return to production and operation. All sales, technical support, manufacturing, logistics and customs clearance services are now fully restored and ready to serve global customers.

The MJ6132TY Sliding Panel Saw boasts outstanding technical specifications and is ideal for large-scale production needs: the table guide dimension is 3200mm*375mm, the maximum cutting height at 90° is 80mm, the main saw blade diameter is 300mm (customizable), the main saw speed is 4000/6000r.p.m, and the scoring saw blade diameter is 120mm with a speed of 8000r.p.m.

The HT400 NOVA sliding table saw, manufactured by Qingdao Holztech Machinery Co., Ltd., is designed for both professional and industrial woodworking applications. With a generous table size of 3200mm in length and optional widths, this model offers exceptional rip and cross-cut capacities of 1400mm and 3200mm respectively. It is equipped with a 400mm main blade and a 120mm scoring blade, allowing a maximum cutting depth of 140mm at 90 degrees. Powered by a robust 5.5+1.1kw motor, the saw delivers high performance and reliability.

This CNC router features a high-stability aluminum worktable that provides a flat and durable surface for various material processing applications. Workpieces are securely fixed using reliable clamping mechanisms, ensuring they remain in precise position during high-speed cutting and engraving operations. This secure holding system makes the CNC router particularly suitable for processing wood, plastics, and non-ferrous metals where precision and stability are essential for quality output in sign making, furniture components, and prototyping work.

The MJ6132TY sliding table saw is perfect for cutting panel materials like MDF, fiberboard, chipboard, laminated panels, and solid wood blanks. It comes with a preliminary trimming feature to avoid chipping on the lower edge, giving you smoother, cleaner cuts.

The single-sided Automatic edge bander is designed for bonding rectangular workpieces with various edge materials: PVC, ABS, acrylic. Our HT450YF has eight functions, including pre-milling, gluing, end cutting, rough trimming, fine trimming,corner rounding, scraping and polishing. It’s a full functions model.

Our Double-Sided Wide Belt Sander is engineered for stable and efficient operation, combining precision, durability, and high performance. The machine features a robust U-steel frame (200×6mm), stronger than nonstandard 140×5mm frames, and driven rolls with a larger 180mm diameter for smoother sanding.

Amidst the wave of technological innovation and human resource enhancement, the machinery industry is constantly seeing the emergence of new products. However, the sliding panel saw remains an essential piece of equipment in almost every production workshop. Easy to operate, stable, safe, and efficient, the sliding table saw is indispensable in the large-scale, standardized, mechanized, and specialized processes of furniture manufacturing, playing a crucial role in the furniture production process.

We have officially launched our revolutionary product—the "Precision Engineering" series fully automatic five-function edge banding machine—to the global woodworking and furniture manufacturing industry. This equipment integrates five core functions: preheating, gluing, end cutting, precision finishing, and edge polishing. With an astonishing processing speed of up to 12 meters per minute and superior edge banding quality, it aims to significantly improve production efficiency and reduce overall costs for enterprises, marking a new stage in intelligent edge banding solutions.

The Holztech HT306Y edge banding machine redefines expectations by delivering heavy-duty processing capability within a remarkably compact footprint. This innovative design allows workshops with limited floor space to access industrial-grade performance previously only available in much larger machines. The edge banding machine achieves this through intelligent engineering that maximizes its internal mechanism efficiency while minimizing its overall dimensions, creating an ideal solution for small to medium-sized furniture manufacturers seeking powerful yet space-efficient equipment.