Introducing You to Industry Basics: The Sliding Table Saw

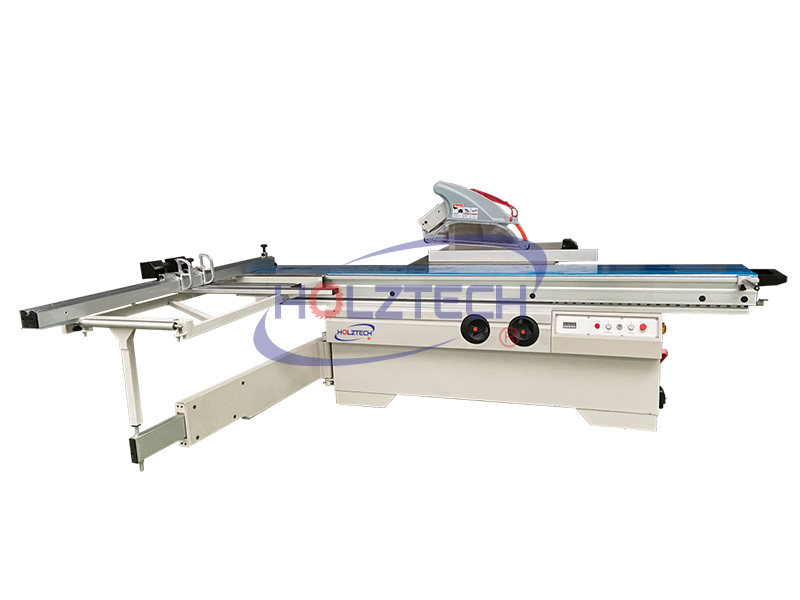

Amidst the wave of technological innovation and human resource enhancement, the machinery industry is constantly seeing the emergence of new products. However, the sliding table saw remains an essential piece of equipment in almost every production workshop. Easy to operate, stable, safe, and efficient, the sliding table saw is indispensable in the large-scale, standardized, mechanized, and specialized processes of furniture manufacturing, playing a crucial role in the furniture production process.

I.Precautions for Using a Sliding Table Saw

When using a sliding table saw, ensure the workpiece is fixed in place and the profile is positioned in accordance with the cutting direction to prevent abnormal cutting. Avoid applying lateral pressure or making curved cuts. Feed the saw smoothly, avoiding impact contact between the blade and the workpiece. The feed speed should not be too fast to prevent tooth breakage and damage.

During use, if any abnormal sounds or vibrations, rough cut surfaces, or unusual odors are detected, stop operation immediately, inspect the saw, and troubleshoot to prevent accidents.

During dry cutting, avoid prolonged continuous cutting to prevent affecting the saw blade's lifespan and cutting quality. When cutting with a wet blade, add water and take precautions against electrical leakage.

II. Tips for Maintaining a Sliding Table Saw

1. Depending on the workload, regularly clean the inside of the sliding table saw to ensure proper motor cooling.

2. Regularly clean the sliding table saw tracks to ensure smooth operation.

3. Regularly inspect the sliding table saw belts and replace them promptly if wear is found.

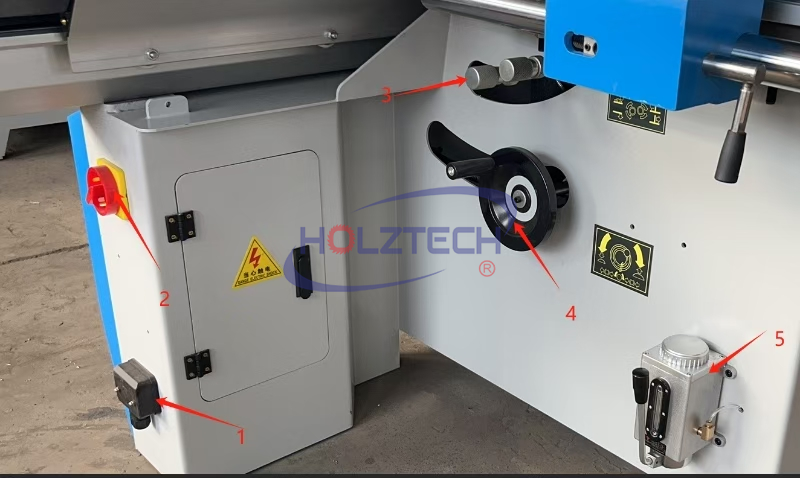

4. Regularly lubricate the parts of the machine body that require lubrication to ensure stable and quiet operation.

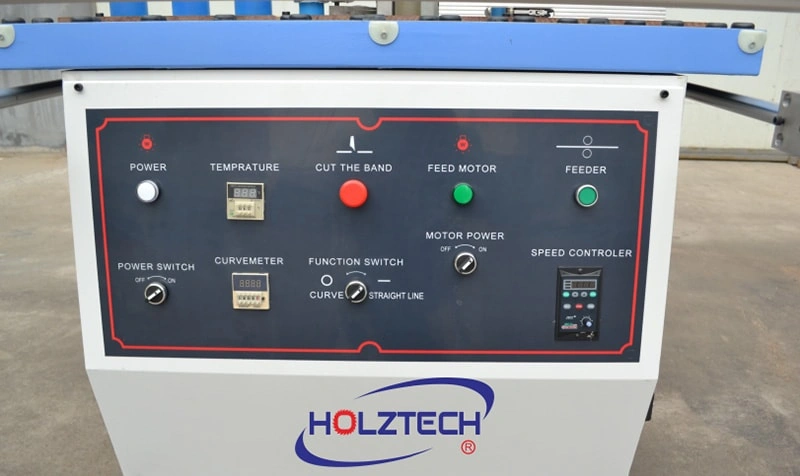

5.Before performing any maintenance, always ensure the power switch is turned off.

By HOLZTECH. Echo