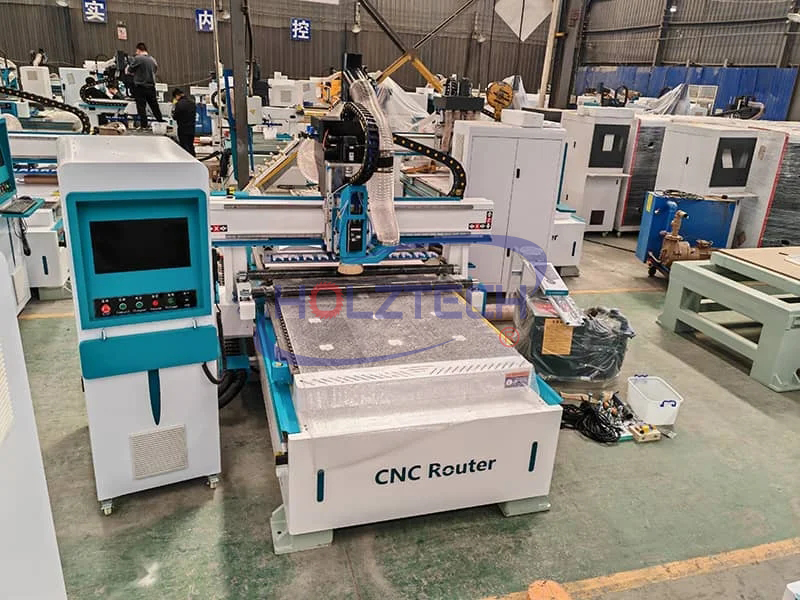

Holztech ATC CNC: Advanced Automatic Tool Changing System

The Holztech ATC CNC router revolutionizes production efficiency with its sophisticated 12-tool automatic tool changing capability. This advanced system offers both linear and carousel-type changers, enabling uninterrupted processing of complex designs without manual intervention. Combined with a standard vacuum table that ensures secure material holding across the entire surface, this CNC machine dramatically reduces downtime between operations. The seamless integration of multiple tools allows for completing intricate milling, drilling, and carving tasks in a single setup, maximizing productivity.

High-Performance Specifications for Precision Machining

Engineered for exceptional performance, this CNC router features a powerful 9kW air-cooled spindle that maintains consistent power output throughout extended operation. With rapid movement speeds reaching 80m/min and processing speeds up to 25m/min, the machine delivers outstanding productivity without compromising on the remarkable 0.02mm positioning accuracy. These technical specifications make this CNC system particularly suitable for high-precision applications in sign making, furniture production, and aluminum composite panel processing, ensuring both speed and exceptional finish quality.

Comprehensive Customization for Specific Requirements

Understanding that every workshop has unique needs, Holztech offers extensive customization options for this CNC router. Beyond standard models, manufacturers can request custom table sizes to accommodate specific workpiece dimensions, along with personalized appearance options to match existing workshop equipment. This flexibility extends to the machine's structural configuration, allowing businesses to optimize their floor space and workflow efficiency with a CNC solution that truly fits their operational requirements and production environment.

Enhanced Capabilities Through Optional Accessories

The versatility of this CNC system is further expanded through numerous optional accessories. Workshops can integrate roller presses for processing uneven surfaces, side-mounted bodies for space optimization, and custom tool heads for specialized materials. The availability of an automatic feeding system transforms the machine into a semi-automated production line, significantly reducing labor requirements while increasing output. These strategic enhancements make this CNC router a scalable solution that grows with your business needs.