Holztech Sanding Machine: Efficient Solution for Post-Laser Cutting Metal Finishing

Holztech sanding machine is not only widely used in woodworking, but also shows excellent performance in the metalworking industry. After laser cutting, perforated steel plates and iron sheets often have burrs or rough edges. Our sanding machine can effectively grind and smooth these surfaces, improving the overall quality of the workpieces and making them more suitable for welding, coating, or assembly.

Our sanding machine is designed with multiple advanced functions, including wide-belt sanding for stainless steel, thickness calibration sanding, deburring, and mirror surface finishing. For perforated metal materials, deburring and edge polishing are particularly important. To further enhance processing accuracy, our sanding machines can also be equipped with vacuum adsorption or magnetic adsorption systems. These features ensure stable holding of the workpieces during operation, providing greater safety and precision, even when dealing with thin or complex perforated sheets.

With the growing use of laser cutting in the metal industry, manufacturers face the challenge of handling intricate details and removing burrs efficiently. Holztech sanding machine offers an ideal solution with high efficiency and automation, significantly reducing manual labor while ensuring consistent and high-quality results. By combining multiple functions into one, our product helps clients improve productivity, reduce costs, and increase competitiveness in today’s demanding markets.

In conclusion, our sanding machine provides a reliable and cost-effective solution for post-laser cutting finishing of perforated metal sheets. It not only delivers smooth, precise surfaces but also guarantees efficiency, safety, and durability, making it the right choice for manufacturers who pursue higher standards

By: Holztech. Mia

Related News

We have officially launched our revolutionary product—the "Precision Engineering" series fully automatic five-function edge banding machine—to the global woodworking and furniture manufacturing industry. This equipment integrates five core functions: preheating, gluing, end cutting, precision finishing, and edge polishing. With an astonishing processing speed of up to 12 meters per minute and superior edge banding quality, it aims to significantly improve production efficiency and reduce overall costs for enterprises, marking a new stage in intelligent edge banding solutions.

The Holztech HT306Y edge banding machine redefines expectations by delivering heavy-duty processing capability within a remarkably compact footprint. This innovative design allows workshops with limited floor space to access industrial-grade performance previously only available in much larger machines. The edge banding machine achieves this through intelligent engineering that maximizes its internal mechanism efficiency while minimizing its overall dimensions, creating an ideal solution for small to medium-sized furniture manufacturers seeking powerful yet space-efficient equipment.

Featuring SCM-inspired design, cast iron motor group, and heavy-duty steel body for unparalleled durability and performance.

The HT450A single-sided edge bander machine is designed for modern furniture producers who demand precision, efficiency, and versatility. It’s perfect for working with PVC, ABS, and acrylic materials, ensuring seamless bonding for rectangular workpieces.

Our hot press machine is a core piece of equipment in panel furniture production. Utilizing precise temperature control and hydraulic pressurization technology, it enables rapid pressing and bonding of MDF, plywood, and veneer panels. The equipment features constant temperature and pressure regulation, resulting in high pressing strength, a smooth and flawless board surface, and adaptability to the processing needs of boards of varying thicknesses, effectively improving the bonding quality and production efficiency of furniture panels.

The Holztech finger grafting machine offers exceptional flexibility by processing wood segments into desired lengths ranging from 3000mm to 4500mm. This capacity makes it an ideal solution for producing long structural components used in construction, furniture frames, and architectural elements. By automating the critical process of creating extended wooden beams from shorter pieces, this finger grafting machine enables manufacturers to utilize material efficiently while meeting precise dimensional requirements for various industrial and commercial applications.

Our Manual Edge Banding Machine delivers precision, versatility, and efficiency for small to medium woodworking workshops.

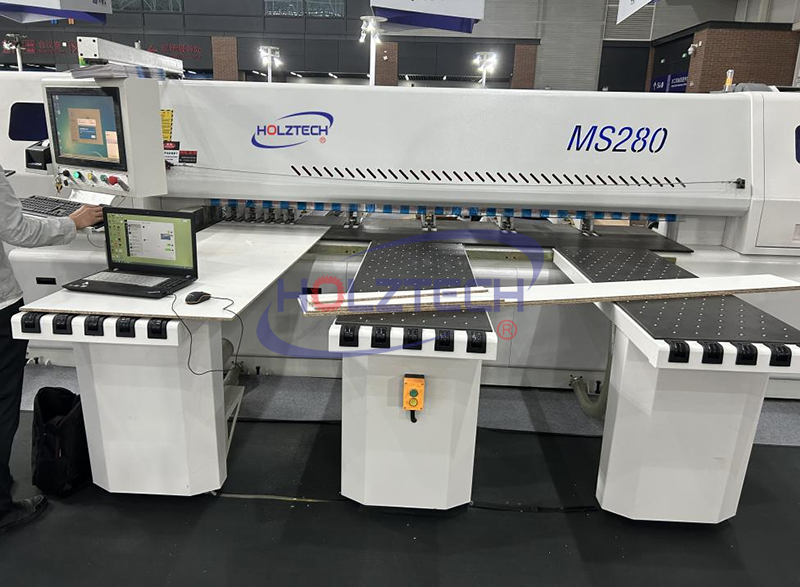

Our CNC Beam Saw is designed for high-quality batch cutting of laminated chipboard and fibreboard to revolutionize production efficiency and processing quality in panel furniture manufacturing. Offering three standard processing sizes—2800mm, 3200mm, and 3800mm—the equipment precisely meets the standardized production demands of cabinetry, wardrobes, and office furniture sectors, providing robust equipment support for large-scale customized production.

The furniture manufacturing industry has a powerful new tool for precision and efficiency with the launch of the Compact Edge Banding Machine Model HT306Y. This innovative machine integrates six essential finishing processes into a single, streamlined unit, offering exceptional versatility and space-saving design for small to medium-sized workshops and custom furniture production lines.

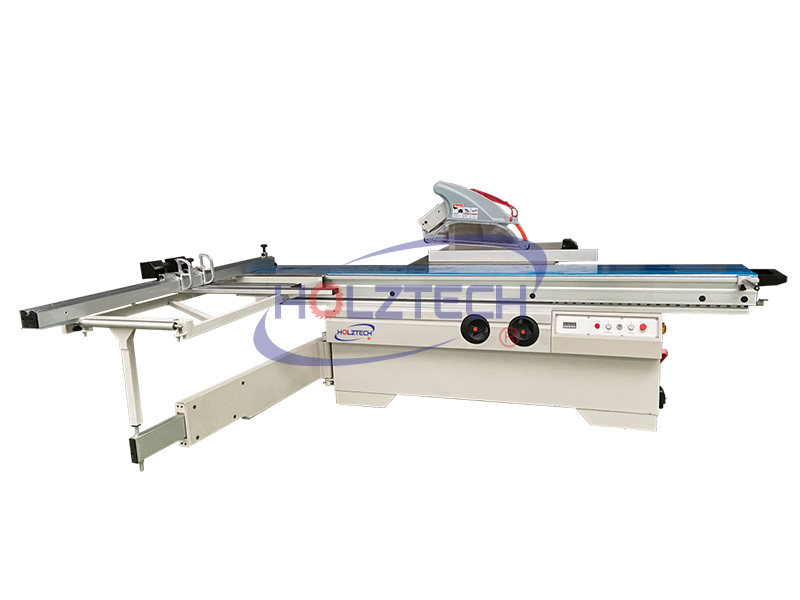

The Holztech MJ6116TY is a space-saving sliding table saw that delivers high cutting efficiency despite its compact footprint. Engineered specifically for small to medium-sized workshops and factories with regular wood panel cutting needs, this machine brings professional-grade precision and productivity to environments where floor space is limited. Its intelligent design ensures this sliding table saw performs robust cutting tasks while occupying minimal workshop area, making it an ideal entry-level or secondary machine for custom furniture makers and cabinet shops.