HOLZTECH: A Look at the 10,000 sqm Woodworking Machinery Powerhouse in Qingdao

Qingdao, China— In the industrial heart of Huangdao District, Qingdao, a modern woodworking machinery manufacturing base is gaining global attention for its robust capabilities and innovative spirit. This is the core production facility of HOLZTECH. We recently toured this 10,000-square-meter modern factory to uncover the secrets behind its full-spectrum manufacturing process, from raw materials to precision equipment.

1. A 10,000-Square-Meter Facility: The Foundation for Scalable Production

The HOLZTECH factory is strategically located in Huangdao District, Qingdao, a key industrial and logistics hub that provides excellent access to supply chains and global shipping routes. The first thing that strikes you upon entering is the scale of the operation. The vast, 10,000-square-meter workshop is intelligently zoned for different production stages. With its high ceilings, clean floors, and orderly assembly lines, the facility exemplifies modern manufacturing management and provides a solid foundation for high-volume, efficient production.

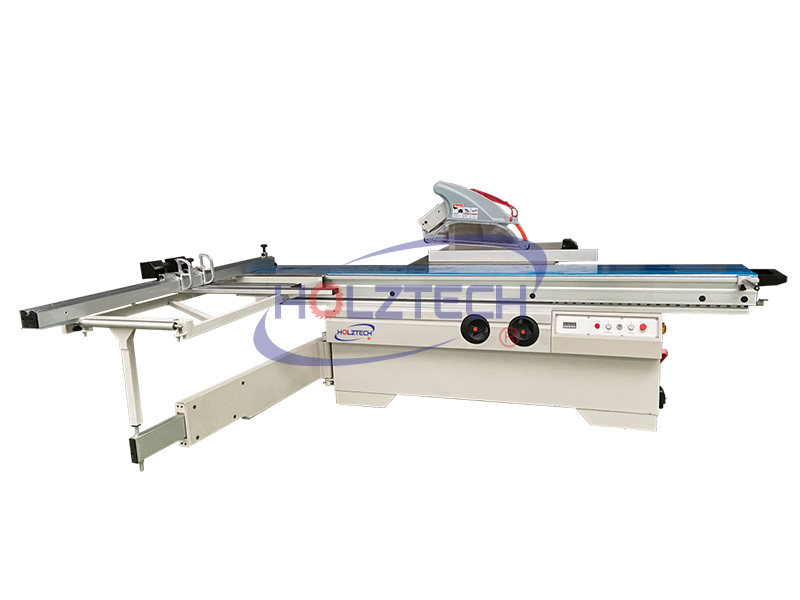

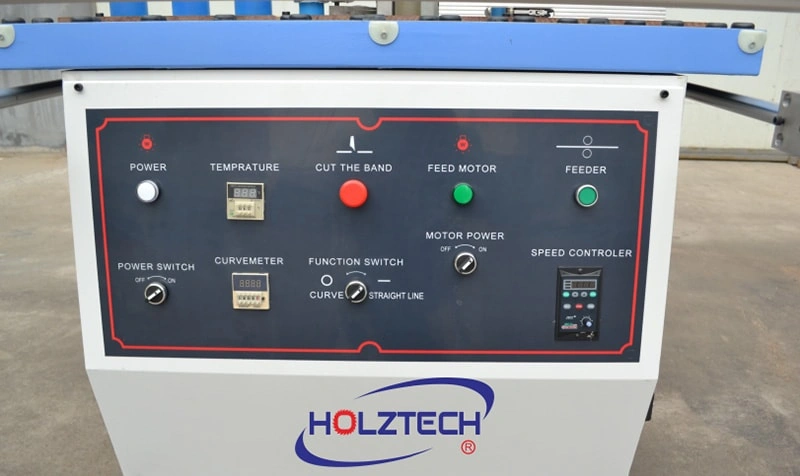

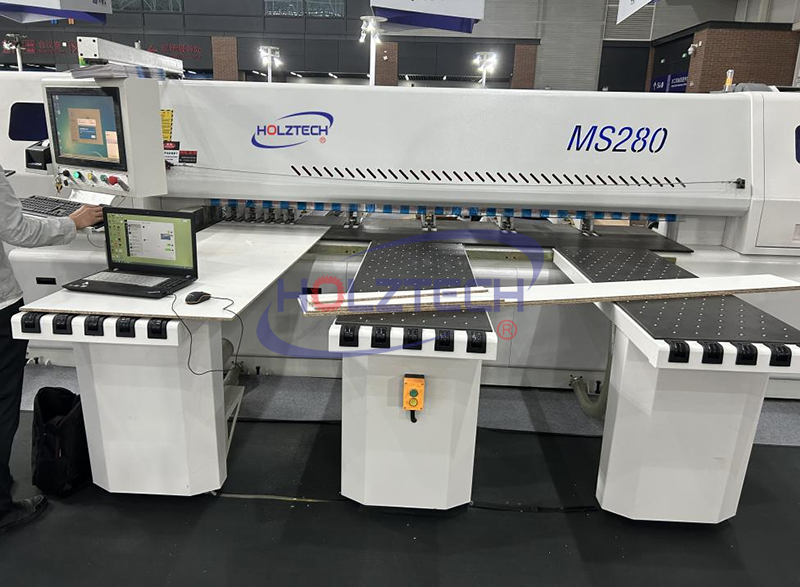

2. Comprehensive Product Range for Diverse Woodworking Needs

The production lines showcase HOLZTECH's core product series. A variety of precision panel saws, electronic cutting saws, and CNC routers are being assembled, while on another line, high-efficiency automatic edge banding machines undergo final calibration. HOLZTECH's product portfolio covers almost all critical stages of panel furniture manufacturing, from cutting and edge banding to drilling and sanding. This allows the company to offer one-stop-shop equipment solutions for furniture manufacturers, catering to needs ranging from large-scale production to bespoke custom processing.

3. Vertical Integration: Total Quality Control from Casting to Assembly

"Quality comes from controlling every detail." This is the principle HOLZTECH lives by. Unlike many assembly-only plants, HOLZTECH's key competitive advantage is its vertically integrated manufacturing process. The factory houses dedicated foundry and machining workshops. Critical components are cast in-house and then precision-machined using CNC equipment, ensuring the fundamental rigidity and accuracy of every part. This approach eliminates the risks associated with inconsistent quality from external suppliers, allowing for seamless control over the performance, stability, and durability of every machine that leaves the factory.

4. Customization Services: Becoming Your Exclusive Manufacturing Partner

In a competitive market, HOLZTECH's other major strength is its powerful customization capability. The factory does not just engage in standard production; it employs an experienced team of R&D engineers. This team works closely with clients to understand their specific production processes, material characteristics, and capacity requirements, offering "tailor-made" solutions. Whether it's a saw for special dimensions, an edgebander with non-standard functions, or an automated production line, HOLZTECH can leverage its technical expertise to develop the perfect machine for the task, acting as a true strategic partner in its clients' growth.

Conclusion

This visit revealed that HOLZTECH is more than just a modern factory; it is a hub of manufacturing excellence and forward-looking innovation. With the scale of its facility, a comprehensive product range, complete vertical integration, and flexible custom solutions, HOLZTECH is firmly positioning itself as a leading force in the global woodworking machinery market, dedicated to creating greater value for woodworking professionals worldwide.

Leo