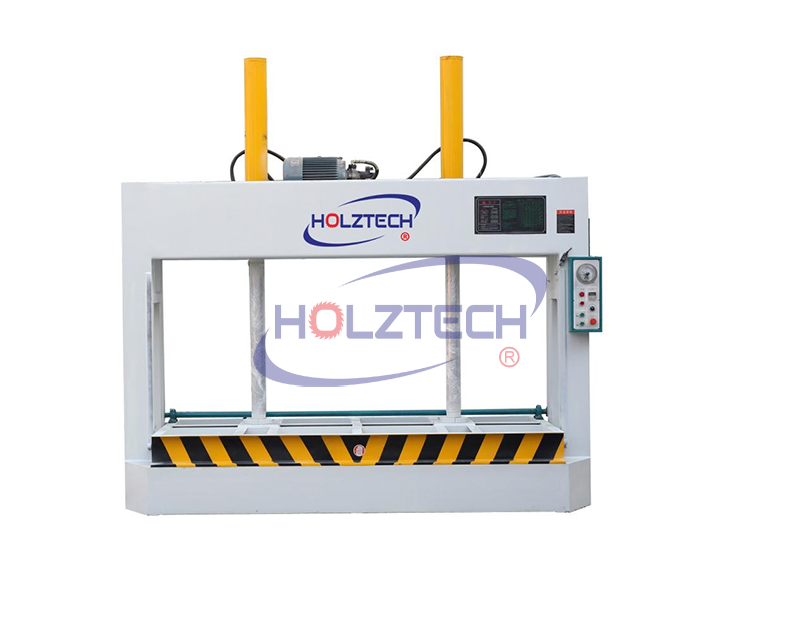

Engineered for Precision and Durability: HOLZTECH Machinery Launches New Generation 50-Ton Heavy-Duty Woodworking Cold Press

Fully Welded Frame and Engineering-Grade Hydraulic System Define a New Standard for High-End Panel Processing

HOLZTECH Machinery, a company specializing in high-end woodworking machinery manufacturing, today officially launched its new generation HT-50 series heavy-duty cold press. Designed to address precision challenges in panel processing caused by uneven pressure and equipment deformation, this model, with its revolutionary fully welded frame structure and high-quality hydraulic system derived from engineering machinery, provides an efficient, stable, and durable ultimate solution for the furniture manufacturing, door and window production, and custom cabinetry industries.

I. Solid Foundation: Fully Welded Frame Eliminates High-Pressure Deformation

In traditional manufacturing, some cold presses use spot welding. Under long-term high-pressure cyclic operation, stress concentrations at the weld points can easily cause micro-deformation, leading to unevenness in the pressing platform and ultimately affecting the uniformity of panel lamination.

The HOLZTECH HT50 series completely abandons this old approach, adopting a one-piece, fully welded frame. This process creates a rigid, uniformly stressed body, effectively resisting deformation even under decades of 50-ton full-load operation, ensuring the long-term levelness of the pressing platform and providing stable and reliable precision for every lamination

II. Powerful Core: Engineering-Grade Hydraulic Power

The reliability of the hydraulic system directly determines the efficiency and lifespan of the cold press. The core power source of the HT-50 series comes from two high-quality hydraulic cylinders with a diameter of 125mm. The materials, sealing technology, and process standards used are the same as those in large-scale engineering machinery hydraulic systems. This "downscaling application" ensures: 1. Extreme stability under ultra-high pressure: The dual cylinders (2 pieces in total) collaboratively provide a stable pressure of up to 50 tons.

2. Extremely low leakage and attenuation rate: After rigorous testing, it maintains stable pressure during long-term use, reducing energy loss.

3. Longer service life and lower maintenance requirements: Durability far exceeds that of ordinary industrial hydraulic components. 3. Tailored for High-Efficiency Production

Beyond its robustness and power, the HT-50's design fully considers the production needs of modern workshops:

Spacious working surface: The standard size of 2500*1250mm easily handles large standard sheet materials, improving the efficiency of batch operations.

Optimized working height: The 980mm opening height balances the need for inserting multiple layers of blanks with operator comfort, reducing labor intensity.

Efficient and energy-saving power: Equipped with only a 4kw high-efficiency motor, it provides immense pressure while optimizing energy consumption, lowering long-term operating costs.

4. Technical Parameter Summary:

Maximum Pressure: 50 Tons

Working Dimensions: 2500 * 1250 mm

Working Height: 980 mm

Number of Cylinders: 2 Pieces

Cylinder Specifications: Φ125 * 82 mm

Motor Power: 4 kw

By Tina