A New Benchmark for Precision Manufacturing

A New Benchmark for Precision Manufacturing: The HT600Y Fully Automatic Edge Banding Machine Leads Industry Innovation with its 15m/min High-Speed and Diamond Milling Technology

Integrating six functions, its cast aluminum base design enables ultra-stable precision machining, injecting efficient and intelligent new power into the furniture and custom home furnishing industry.

In today's era of Industry 4.0 and intelligent manufacturing sweeping the global manufacturing industry, the HT600Y, a fully automatic edge banding machine integrating high efficiency, high precision, and high stability, has officially debuted. Its processing speed of up to 15m/min and numerous innovative designs are redefining industry standards for board edge banding operations, bringing breakthrough solutions to the furniture manufacturing, custom home furnishing, and woodworking machinery industries.

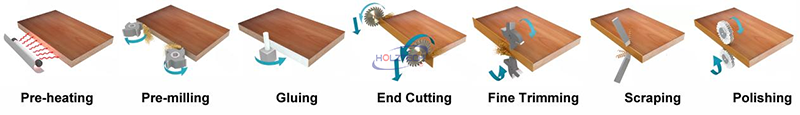

Integrated Design, Six-Step Precision Processing: Full-Process Automation Empowers Precision Manufacturing

The core advantage of the HT600Y lies in its highly integrated fully automatic operation process. A single machine can seamlessly complete all six key processes from gluing to polishing.

Innovative Design, Stability is King: Cast Aluminum Base Achieves Millimeter-Level Precision

The HT600Y has made revolutionary improvements to its core structure. Its key components, such as the end-trimming motor, are all mounted on a high-strength cast aluminum base. Compared to traditional welded bases, the cast aluminum base offers the following unparalleled advantages:

Exceptional Stability: Effectively absorbs and counteracts vibrations generated during high-speed operation, providing a solid guarantee for continuous high-precision machining.

Ultimate Precision: The base itself experiences virtually no stress deformation, ensuring the cutter head remains in the most precise machining position for extended periods, achieving industry-leading tolerance control.

Durability: Excellent corrosion resistance and fatigue strength extend the service life of critical components, reducing long-term maintenance costs.

Leap in Efficiency, Doubling Capacity: Setting a New Speed Benchmark at 15 meters per minute

While ensuring top-tier machining quality, the HT600Y elevates production efficiency to a new level. A straight-line edge-sealing speed of 15 meters per minute means it can handle large-volume orders at a pace far exceeding the industry average, helping manufacturing companies easily meet capacity challenges, shorten delivery cycles, and gain a competitive edge in the fierce market.

Market Outlook and Application Scenarios

Faced with the growing demand for personalized custom home furnishings and the ever-increasing requirements for product environmental friendliness and aesthetics, the HT600Y fully automatic edge banding machine is undoubtedly the ideal choice for manufacturing enterprises. It is particularly suitable for:

Large-scale panel furniture production lines

High-end custom cabinet and wardrobe manufacturers

Wood processing plants with stringent requirements for edge banding quality and efficiency

Industry experts commented: "The HT600Y combines high efficiency, high precision, and high stability so exceptionally well. It is not merely an upgrade of a single piece of equipment, but a crucial step in driving the entire panel processing process towards intelligence and lean manufacturing."

Currently, the HT600Y fully automatic edge banding machine has been fully launched in the market and is expected to lead a new wave of production equipment upgrades, helping global manufacturers solidify their quality foundation and win future competition.

By Tina