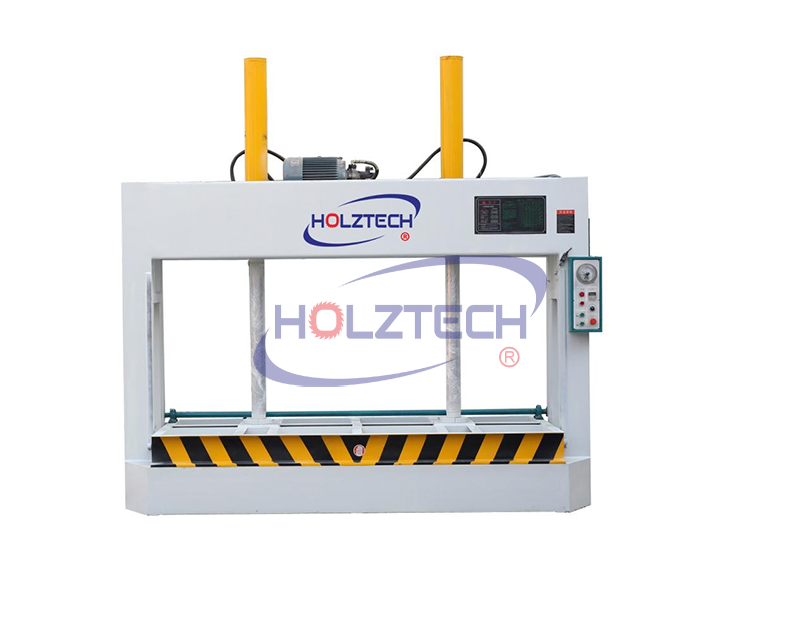

Cold press machine

In the field of woodworking, cold press machine are core equipment for processes such as panel splicing and veneer application, and their performance directly affects the flatness and strength of the finished product. This cold press machine, specifically designed for the woodworking industry, has become a new choice for many processing companies due to its precise pressure control and stable operation, effectively solving problems such as low processing efficiency and uneven product quality associated with traditional equipment.

This cold press machine demonstrates significant advantages in key surface precision indicators. Professional testing shows its surface roughness to be only 0.8μm, while similar high-quality products on the market typically have a roughness of 1.6μm. This finer surface treatment not only improves the machine's wear resistance but also reduces friction damage during panel processing, providing a fundamental guarantee for high-quality panel production. Simultaneously, the machine's hydraulic cylinder features a reinforced design with four sealing rings, forming multiple layers of sealing protection to completely eliminate oil leakage. Even after long-term use, the cylinder remains dry and clean, reducing maintenance costs.

In terms of structural strength, this cold press machine also stands out. The main body of the machine is made of high-strength H-beam steel, while the core crossbeam adopts an integrated forged structure. Compared with the commonly used welded steel plate design on the market, the overall rigidity and resistance to deformation are greatly improved. This design makes the equipment less prone to structural loosening during long-term high-pressure operation, which not only extends the service life of the equipment but also ensures the pressure uniformity of each pressing operation, further improving the qualification rate of the processed products.

By HOLZTECH. Echo