The single-sided edge banding machine is designed for bonding rectangular workpieces with various edge materials: PVC, ABS, acrylic.

Machine Base. Heavy duty machine body with 18mm and 8mm steel thickness. Machine Base.

Robotic welding in one setup,which ensures high precision and longer service life.

Processing on Japanese CNC machining center keeps high precision flatness.

Painting. Electrostatic powder spraying to improve coating corrosion resistant capacity higher and smoother.

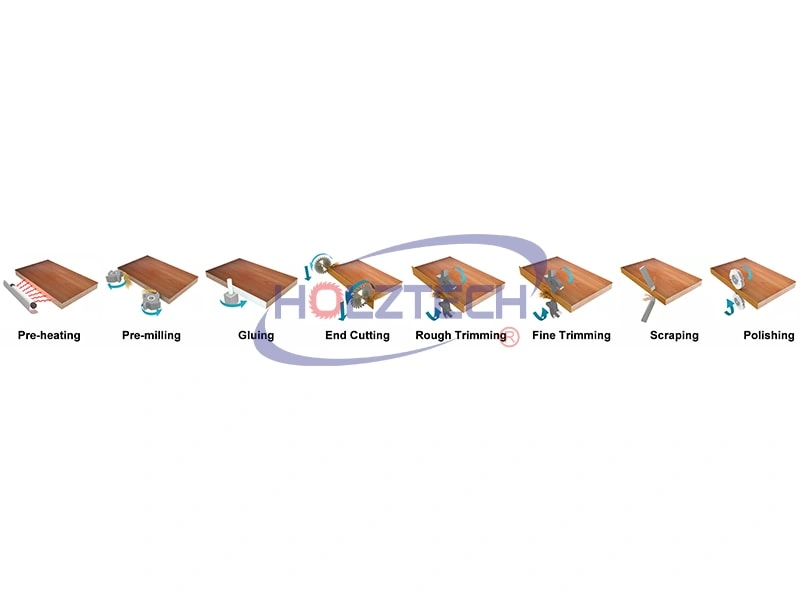

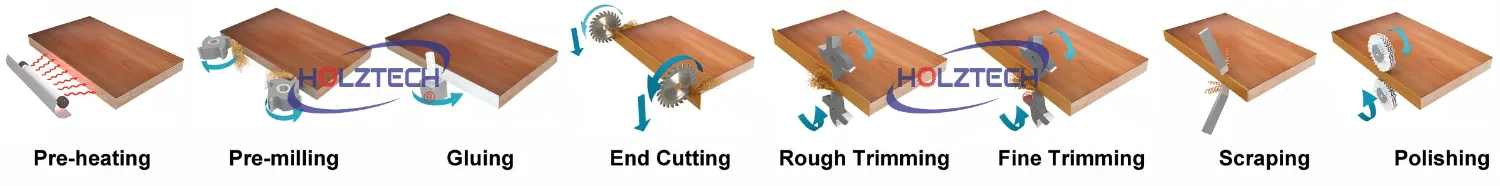

Pre milling. Premilling function is used to eliminate cutting defects (micro chips,steps from the scoring saw),guarantees perpendicular and rectilinear geometry of the end surface of the part.

The glue tank about 3 liters for EVA glue,Teflon coating glue tank is optional,which prevents the glue from sticking to the tank. Glue scrapers on pressing rollers are optional,to clean the extra glue on the rollers.

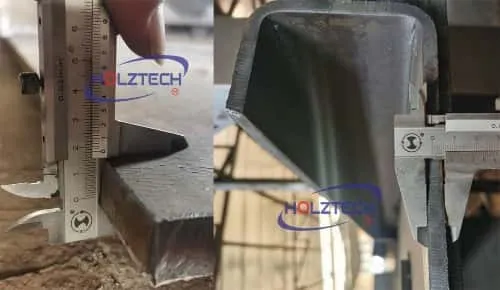

End Trimming. The linear guide is located at an angle of 45° with 2 motors and 2 saw discs. To cut the extra banding tape in high precision.

Rough Trimming,Fine Trimming,Scraping. Large diameter copy wheel - Ø 180 mm and round conical copy wheel Ø 120 mm ensure the accuracy of workpiece positioning. The aspiration system effectively removes chips from the trimming and scraping area. Clean space ensures high quality processing. Scraping is used to remove microwaves on the processed radius surface of the edge after trimming.

Buffing is used to remove microwaves on the processed radius surface of the edge after trimming.

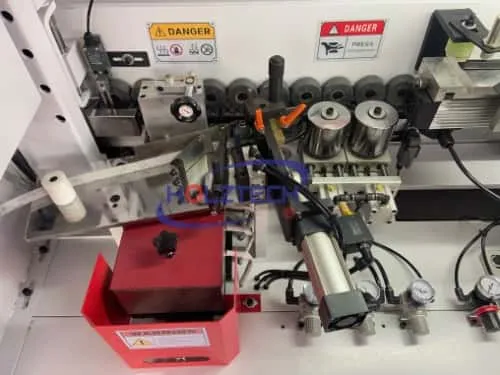

Touch Screen. The operating interface is intuitive and simple,information about the machine status is available at a glance. Display of processes and diagnostic information. Prompt problem solving using the error code displayed on the screen. High quality electrical components from Delta,Omron,Schneider ensure stable electricity and signal supply.

Most components are made by ourselves to control quality with high precision.

Professional Assembly Line. Experienced technicians on professional assembly lines,from the machine bed to small electrical components,ensure the stable and productive operation of the machine.

| Banding Tape Thickness | 0.3-3mm |

| Banding Tape Width | 12-60mm |

| Workpiece Thickness | 10-55mm |

| Workpiece Length | >=80mm |

| Workpiece Width | >=45mm |

| Feeding Speed | 12m/min |

| Heating Power | 1.8kw |

| Pre-milling Motor Power | 1.8kw x 2 |

| Feeding Motor Power | 1.5kw |

| Glue Spreading Motor Power | 0.75kw |

| End Trimming Motor Power | 0.37kw x 2 |

| Fine Trimming Motor Power | 0.75kw x 2 |

| Rough Trimming Motor Power | 0.75kw x 2 |

| Polishing Motor Power | 0.18kw x 2 |